From filter materials to evaporators: One-stop solution for home appliance hot melt adhesives

Classification: Company News

Classification: Industry Information

2025-08-06

In the field of home appliance manufacturing, from the fixation of core components to the assembly of casings, the performance of adhesives directly affects the safety, durability and environmental friendliness of the products. As a professional hot melt adhesive manufacturer, our products, with their diverse features and environmental advantages, are widely adapted to all scenarios of home appliance production, covering key links such as filters, electronic components, and shell assembly, providing efficient and reliable bonding solutions for home appliance manufacturers.

I. All-Scenario Coverage: The diverse applications of hot melt adhesives in the home appliance industry

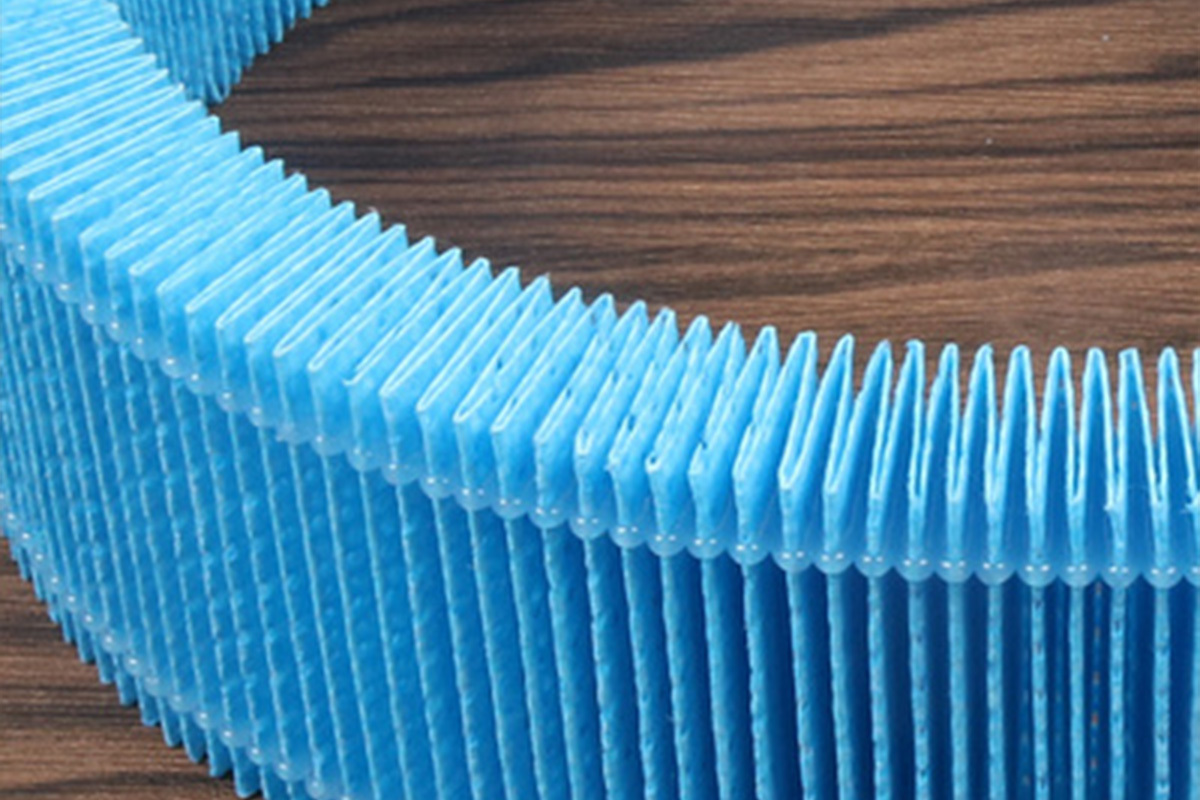

1. Special hot melt adhesive for filtration systems

In the production of filter components for air purifiers and water purifiers, hot melt adhesives play a crucial role. For the frame sealing of flat plate filters, our hot melt adhesive can achieve a tight bond, effectively preventing the leakage of unfiltered air. When used in the process of adhering the filter element to the cover, it can precisely fill the gap, ensuring the sealing performance between the filter element and the housing, and guaranteeing the stable filtration effect. In the edge bonding of cylindrical filters, the uniform coating property of hot melt adhesive ensures that the seams are firm and smooth, and can withstand long-term water flow or air flow impact without delamination.

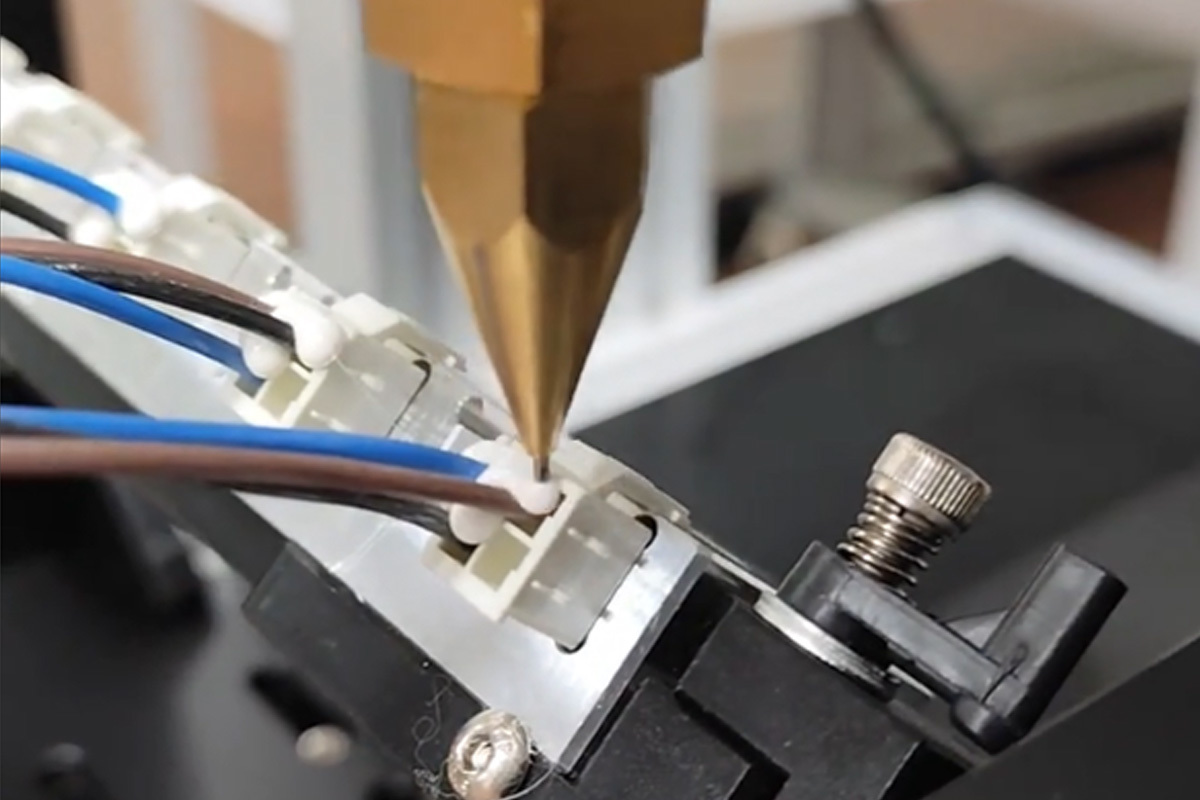

2. Hot melt adhesive for fixing electronic components

The electronic circuit boards inside household appliances have extremely high requirements for the stability and safety of adhesives. Our hot melt adhesive is specially designed for circuit boards. It can reliably fix resistors, capacitors and other components, maintaining stable adhesive force in high-temperature working environments without softening or flowing. It has excellent insulation performance, which can avoid the risk of short circuits in components. At the same time, it is non-corrosive and will not cause damage to the circuit board, ensuring the long-term stable operation of the household appliance circuit system.

3. Hot melt adhesive for the assembly of the shell and structural components

In the assembly of household appliance shells and panels, hot melt adhesives are compatible with various material combinations. When fixing the plastic components of the air conditioner casing, hot melt adhesive can cope with the thermal expansion differences of different plastic materials and reduce the gaps caused by temperature changes. In the connection between the back panel and the frame of a TV set, the high-strength bonding of hot melt adhesive can enhance the overall structural stability and reduce the risk of loosening caused by transportation vibration. The fixation of the washing machine panel and the induction cooker panel relies more on the aesthetic appeal of the hot melt adhesive. After application, there should be no overflow or marks, ensuring a neat and exquisite appearance of the household appliances.

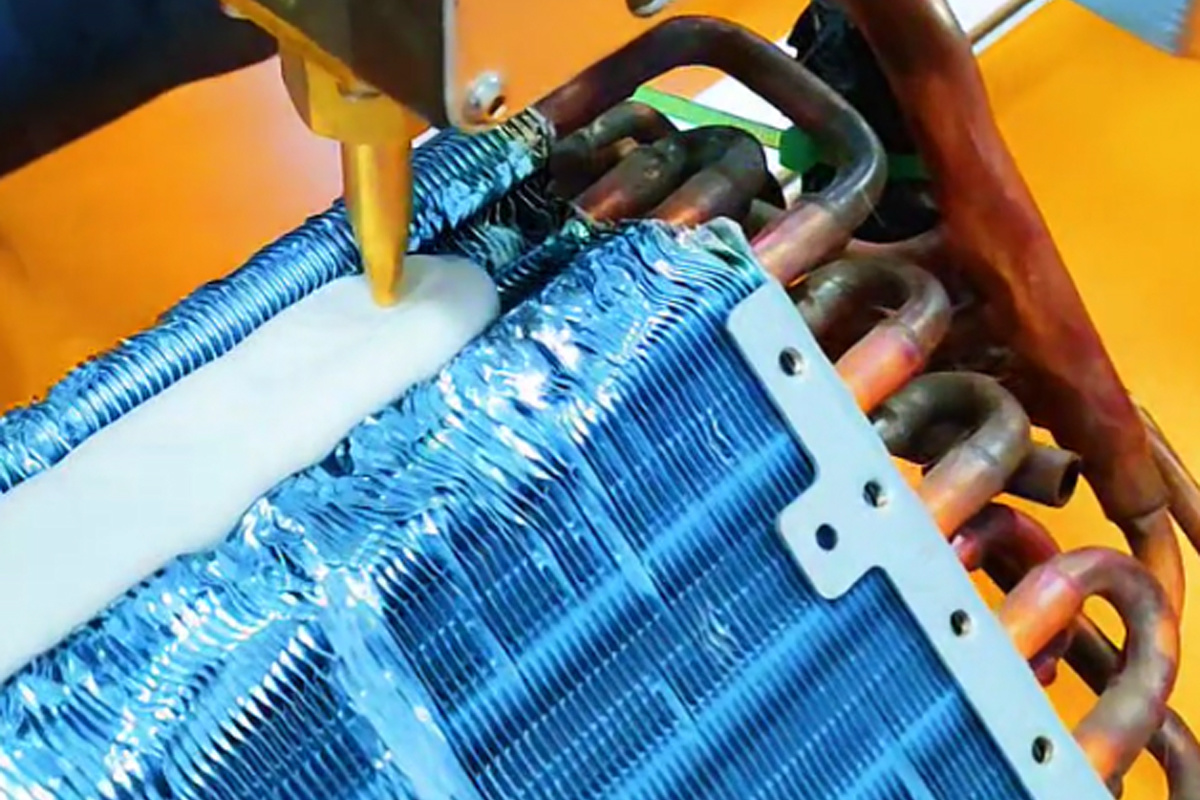

4. Special foaming hot melt adhesive for air conditioners

In response to the special requirements of air conditioning evaporators, our foaming hot melt adhesive can rapidly foam and cure in a low-temperature environment, forming a uniform insulation layer and sealing layer. This hot melt adhesive not only fills the complex gaps in the evaporator, reducing cold energy loss, but also has excellent weather resistance. It maintains stable performance in the high and low temperature alternating environment of long-term operation of air conditioners, helping to improve the energy efficiency ratio of air conditioners.

Ii. Core Advantages: Hot melt adhesives facilitate the upgrading of home appliance production

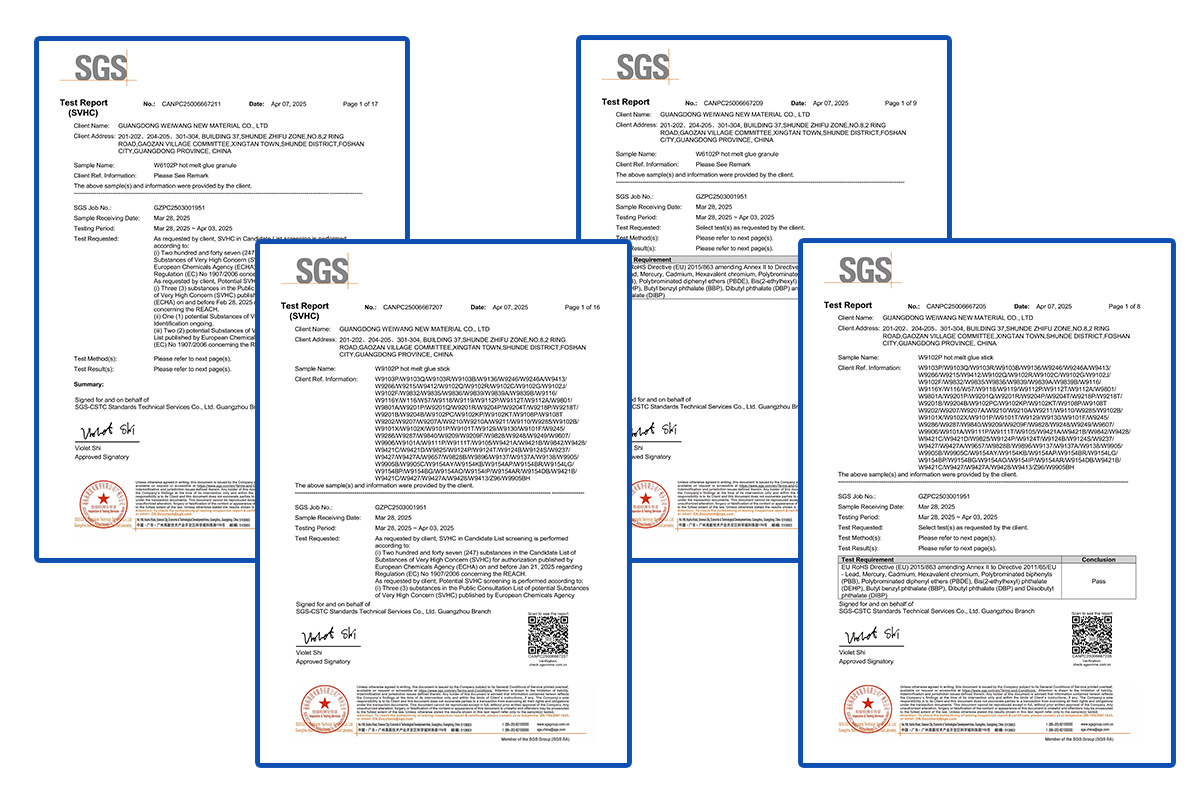

Environmentally friendly and non-toxic, it has passed strict testing

Our hot melt adhesives are made from environmentally friendly base materials. No harmful solvents are added during the production process, and the finished products do not contain toxic substances such as formaldehyde and heavy metals, ensuring the safety of household appliances from the source. All products have passed the EU SGS environmental protection test, comply with international environmental protection standards such as RoHS and REACH, meet the access requirements of domestic and foreign home appliance markets, and help manufacturers avoid environmental protection compliance risks.

2. Strong adhesion and compatibility ensure product durability

Hot melt adhesive has excellent adhesion to various materials commonly used in household appliances, such as plastic, metal, ceramic, and paper, and can meet the bonding requirements of different components. Whether it is the paper filter element and plastic housing of the filter, or the metal pins and plastic base of the electronic circuit board, they can all form a firm connection. Within a specific temperature range, hot melt adhesive has stable performance and can withstand the temperature changes and environmental humidity during the operation of household appliances, reducing product failures caused by bonding failure.

3. Efficient production and optimized manufacturing processes

Hot melt adhesive can solidify quickly after being heated and melted. In most scenarios, bonding can be completed within seconds, without the need for a long waiting time for drying. This feature is compatible with the automated production lines in the home appliance industry, significantly enhancing assembly efficiency and reducing equipment occupation and labor costs in the production process. Meanwhile, the application of hot melt adhesive is precisely controllable, with no stringing or overflow, reducing the subsequent cleaning process and improving the product yield rate.

4. Customized formulas to meet segmented demands

According to the characteristics of different components of household appliances, we offer customized hot melt adhesive formulas. For instance, adhesives used for filters focus on sealing and water resistance, those for electronic components emphasize insulation and high-temperature resistance, while adhesives for casing assembly pay attention to aesthetics and flexibility. A diverse product range enables manufacturers to avoid changing adhesives for different processes, simplifying the procurement and management procedures.

Conclusion

Under the trend of pursuing green manufacturing and quality upgrading in the home appliance industry, hot melt adhesive, with its advantages of being environmentally friendly and non-toxic, having strong adhesion and compatibility, and being highly efficient in production, is becoming an indispensable key material in home appliance manufacturing. Our diverse range of products covers all scenarios including filters, electronic components, and shell assembly. We provide customized solutions to help home appliance manufacturers enhance production efficiency, ensure product quality, and break through environmental protection barriers. As a professional hot melt adhesive partner, we will continue to innovate formula technology to provide strong support for the high-quality development of the home appliance industry.