Preferred choice for fixing electronic wiring harnesses and circuit boards: How does hot melt Adhesive ensure stable electronic connections and efficient production

Classification: Company News

Classification: Industry Information

2025-08-20

In the field of electronic wiring harness and circuit board production, from the terminal fixation of automotive wiring harnesses to the component bonding of circuit boards, the reliability of the connection directly affects the performance and safety of electronic devices. Hot melt adhesive specially developed for the electronics industry, with its core advantages of rapid curing, strong adhesion and good temperature resistance, has become an efficient solution for electronic wire harness production and processing manufacturers.

The core advantage of electronic hot melt adhesive: It precisely meets the requirements of electronic connection

1. Rapid curing to enhance production efficiency

After the hot melt adhesive is heated and melted, the contact wire harness terminals or circuit board components can be cured within seconds, without the need for a long drying wait. Compared with the curing time of traditional adhesives, it can increase the assembly efficiency of electronic wire harnesses by more than 50%, adapt to the high-speed pace of automated production lines, easily meet the demands of batch orders, and reduce the equipment occupation cost in the production process.

2. Strong adhesion ensures a firm connection

Hot melt adhesive can form a tight bond with various materials such as metal terminals, plastic wire harness sheaths, and circuit board substrates. Whether it is the fixation of terminals and wires in automotive wiring harnesses or the pasting of resistors, capacitors and other components on circuit boards, they can withstand frequent vibrations and pulling. They will not fall off or crack over long-term use, significantly reducing the risk of electrical faults caused by loose connections.

3. It has excellent temperature resistance and is suitable for complex environments

Electronic hot melt adhesive can maintain stable performance within a wide temperature range from -40 ℃ to 120℃. In high-temperature environments such as the engine compartment of a car or in low-temperature outdoor conditions, the adhesive layer will not soften or become brittle, ensuring the reliability of the connection between the wiring harness and the circuit board, and meeting the usage requirements of electronic devices in various scenarios.

Ii. Core Application Scenarios: Covering key links of electronic connections

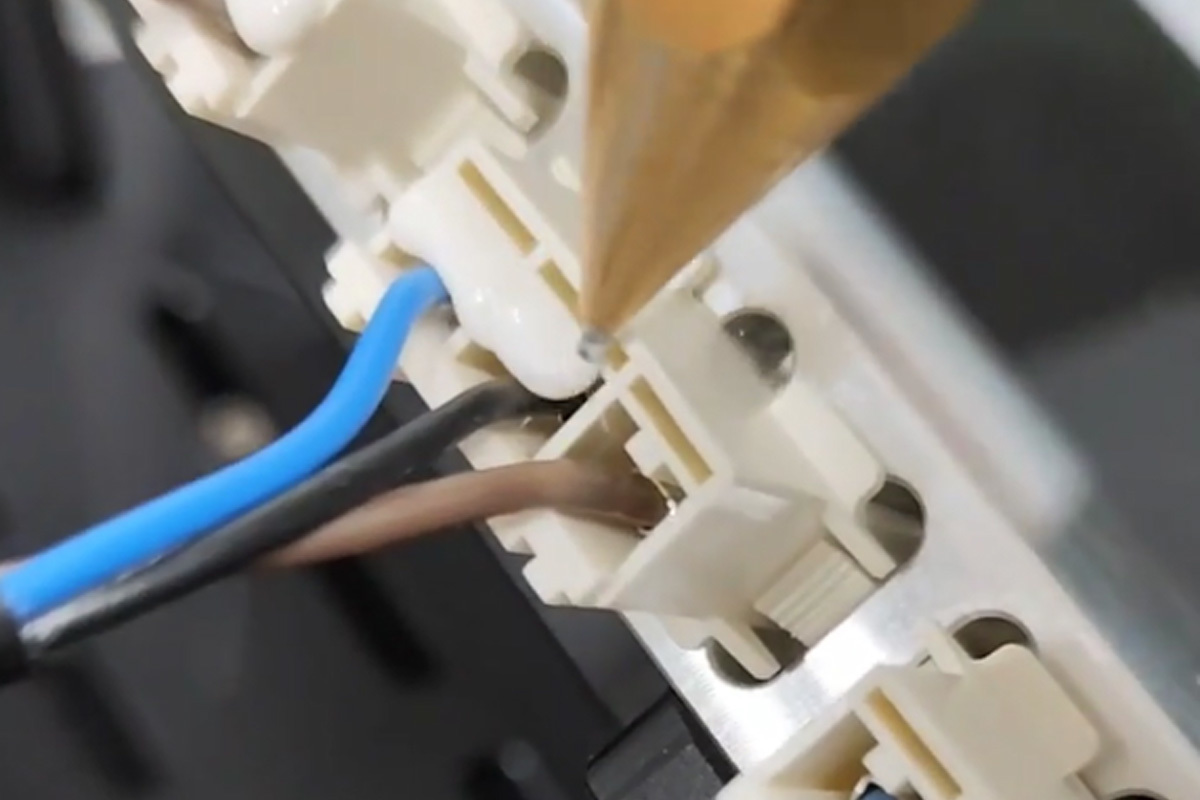

1. Fixation of automotive wiring harness terminals

Automotive wiring harnesses are constantly exposed to vibration and alternating high and low temperatures. The strong adhesion and heat resistance of hot melt adhesive can firmly fix the terminals and wires, avoiding poor contact caused by jolts, ensuring the safe operation of the automotive circuit system, and reducing the risks of after-sales maintenance.

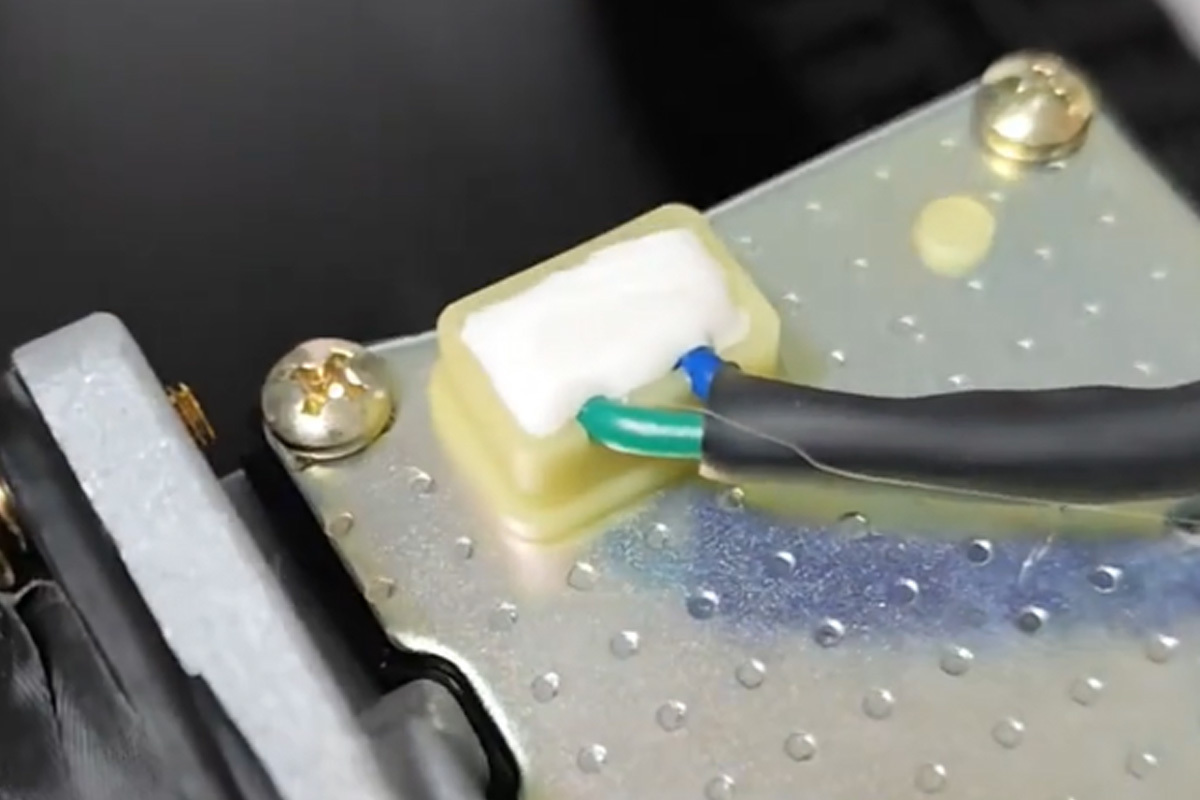

2. General electronic wire harness processing

In the production of wiring harnesses for consumer electronics and industrial equipment, the rapid curing feature of hot melt adhesives is suitable for batch processing of multi-specification wiring harnesses. The characteristics of no stringing and no glue overflow ensure the neat appearance of the wiring harnesses, improve product quality, and meet the assembly requirements of precision electronic equipment.

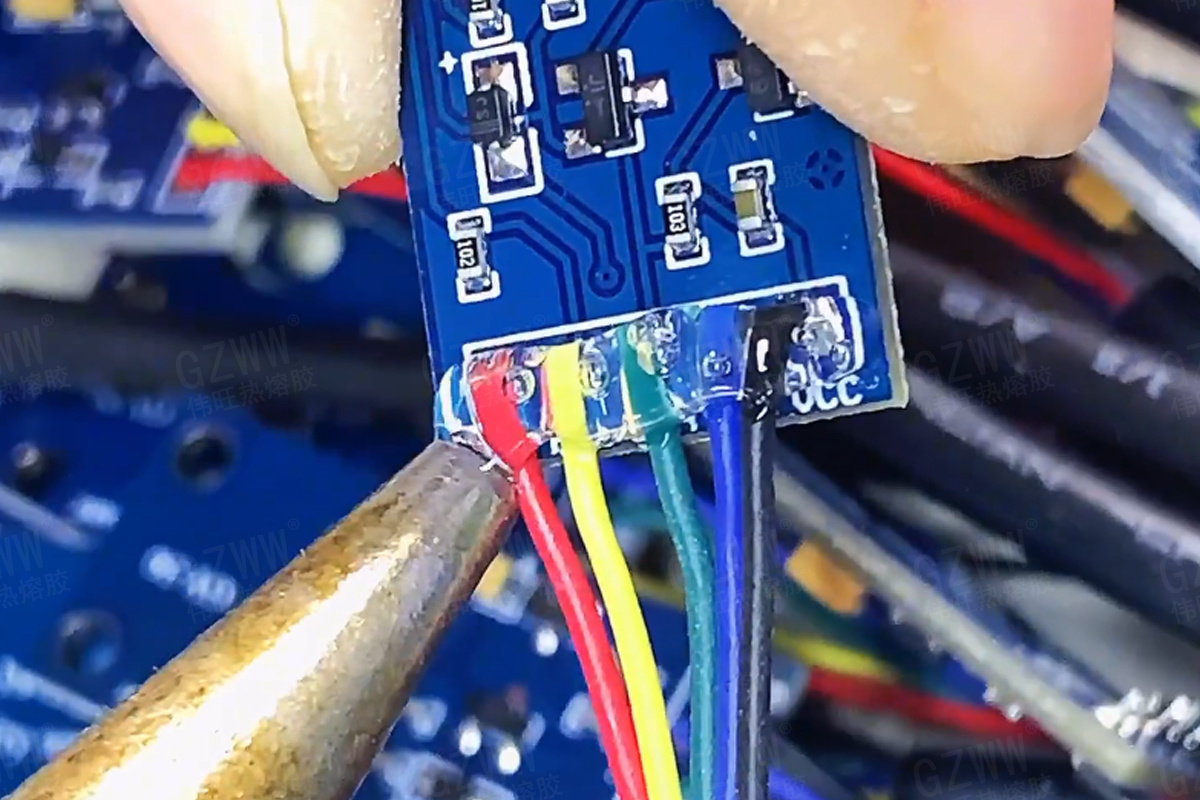

3. Fixing the components on the circuit board

After the small components on the circuit board are fixed with hot melt adhesive, they can effectively resist the thermal shock after soldering and the vibration during equipment operation, enhance the overall structural stability of the circuit board, reduce the risk of short circuits caused by component detachment, and improve the yield of electronic equipment. Iii. Practical Value to the Electronic Wire Harness Industry

Iii. Practical Value to the Electronic Wire Harness Industry

Optimize the production process and reduce costs

Rapid curing reduces the waiting time on the production line. Combined with automated dispensing equipment, it can achieve continuous operation and increase the production capacity per unit time. Strong adhesion reduces the defect rate and rework rate, saving costs for enterprises in terms of both production efficiency and quality.

2. Enhance product reliability and strengthen competitiveness

The high-temperature resistance and strong adhesion properties enable the wiring harness and circuit board to maintain stable performance in complex environments, helping enterprises produce more durable electronic components that meet the strict standards of high-end fields such as automobiles and industries, and gain more recognition from high-quality customers.

3. Simplify process operations and adapt to automation

The application process of hot melt adhesive is simple and does not require complex pretreatment. It can be directly integrated into the automated production line, reducing manual intervention and operational difficulty. This helps manufacturers achieve efficient and standardized production and adapt to the intelligent upgrade trend of the electronics manufacturing industry. Conclusion

Conclusion

Electronic hot melt adhesive, with its advantages of rapid curing, strong adhesion and good temperature resistance, provides a reliable solution for the fixation of electronic wire harnesses and circuit boards. Whether it is automotive wiring harnesses, general electronic wiring harnesses or circuit board processing, production efficiency and product quality can all be enhanced through hot melt adhesives. As a professional hot melt adhesive manufacturer, we are committed to providing customized products for electronic wiring harness enterprises, helping them gain an edge in the fierce market competition.