Choosing the right adhesive for large cardboard packaging: hot melt adhesive with fast drying and strong adhesion, stable bonding of corrugated white card, weather resistance without rework

Classification: Company News

Classification: Industry Information

2025-09-18

In the packaging process of industries such as electronics, beverages, home furnishings, and appliances, the adhesive reliability of large cardboard boxes (such as electronic product packaging boxes, beverage turnover boxes, and home appliance transportation boxes) directly affects product transportation safety and packaging efficiency. Traditional cardboard glue often faces problems such as slow curing, weak adhesion, poor adaptability to cardboard/white card and other cardboard materials, and easy opening when exposed to temperature and humidity changes. However, hot melt adhesive specially developed for large cardboard boxes, with its core advantages of fast curing, strong adhesion, significant adhesion to cardboard/white card, and excellent weather resistance, is becoming an efficient solution for cardboard manufacturers in various industries.

1、 The core advantage of hot melt adhesive for large cardboard boxes: precise matching of packaging needs

1、 The core advantage of hot melt adhesive for large cardboard boxes: precise matching of packaging needs

1. Fast curing, breaking through the bottleneck of packaging production capacity

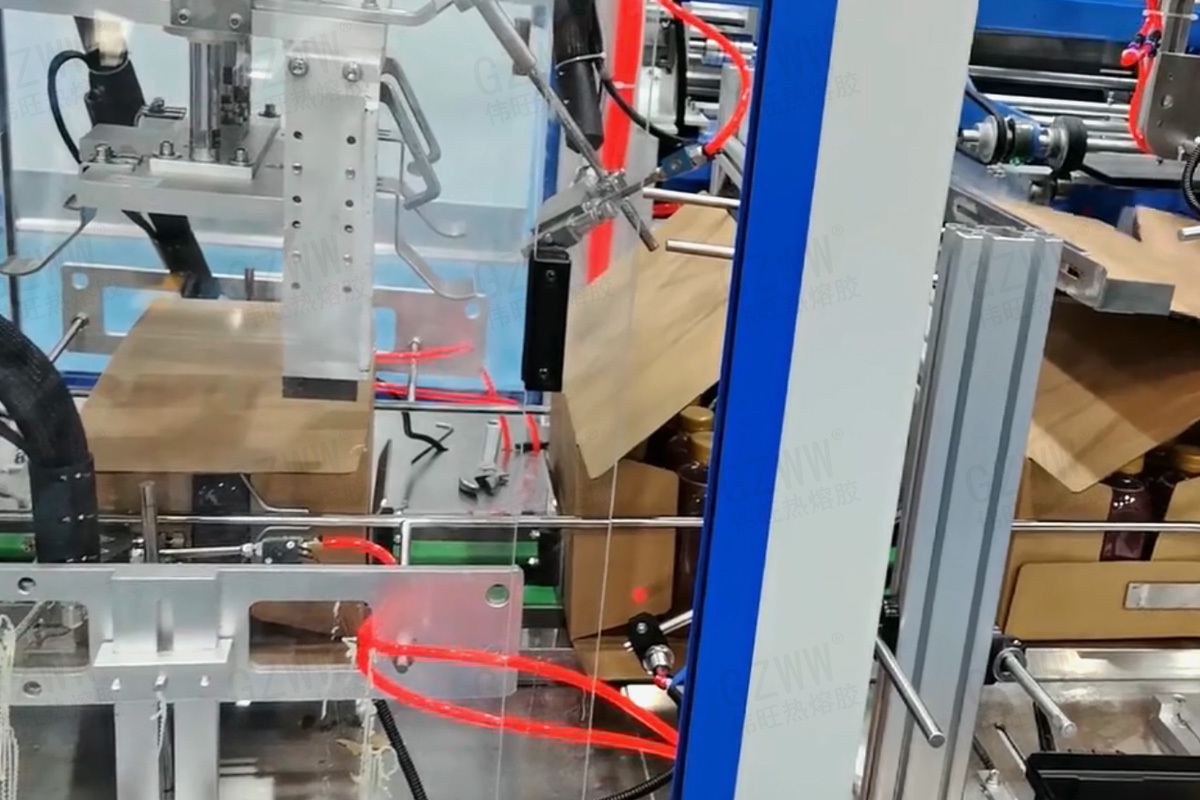

Large cardboard boxes are mostly produced in bulk, and traditional adhesives take tens of minutes or even hours to dry, resulting in serious accumulation on the production line. After being heated and melted, the hot melt adhesive can solidify and shape in just a few seconds when it comes into contact with cardboard, white cardboard, and other cardboard materials. It can keep up with the pace of automated sealing production lines, such as the high-speed sealing line in the beverage industry, which can process 20-30 large beverage boxes per minute. The rapid curing characteristics of hot melt adhesive ensure that each cardboard box immediately enters the next stage after bonding, without waiting for drying. The production efficiency of a single batch is increased by more than 40%, making it easy to meet the demand for large-scale packaging during peak seasons.

2. Strong viscosity ensures stable transportation process

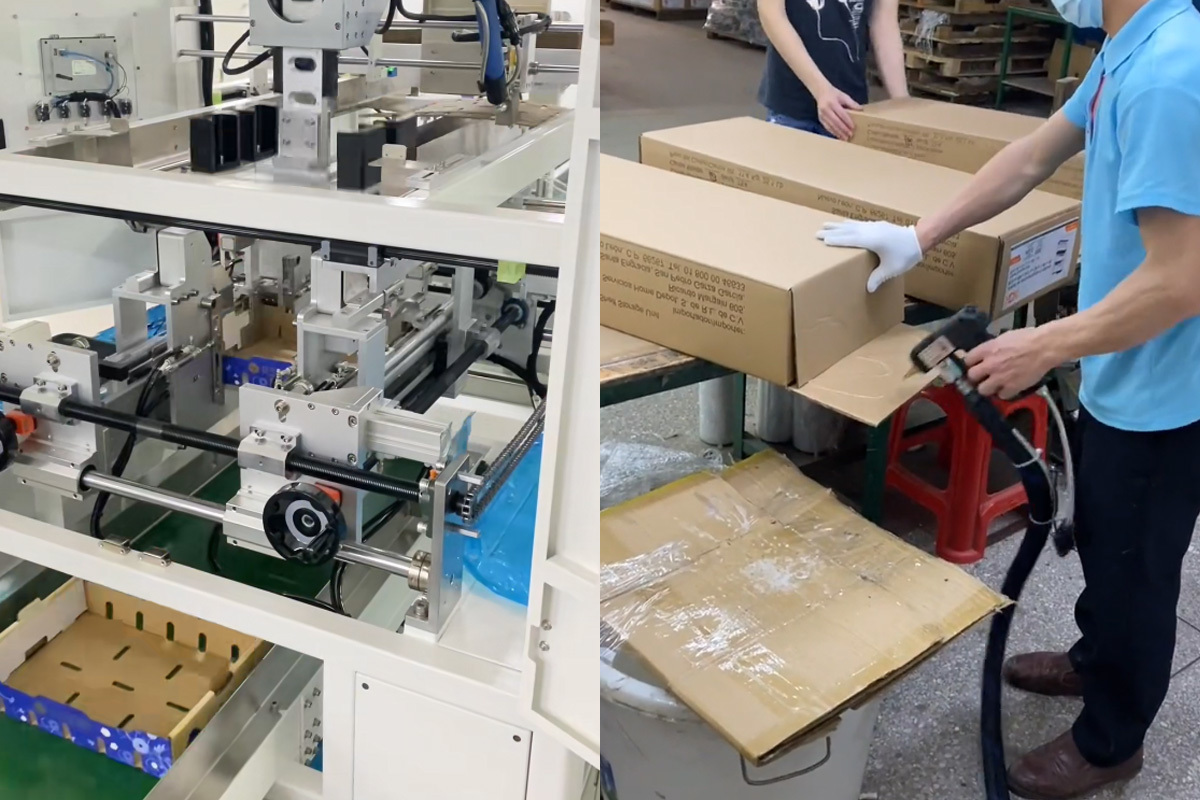

Large cardboard boxes need to withstand stacking pressure, vibration, and handling friction during transportation, and adhesive strength is crucial. Hot melt adhesive has excellent adhesion to commonly used materials such as cardboard, white cardboard, corrugated paper, etc. After curing, the adhesive layer formed has strong toughness and can firmly lock the seams of the cardboard box. For example, electronic product packaging boxes are loaded with precision equipment, and the strong adhesion of hot melt adhesive ensures that the cardboard boxes will not open or become loose during long-distance transportation; The beverage turnover box can be repeatedly loaded, unloaded, and stacked without causing seam cracking due to stress, significantly reducing product transportation loss rate.

3. Significant adhesion to cardboard/white cards, solving the problem of material adaptation

Cardboard and white card have a smooth surface and high density, and traditional adhesives are prone to problems such as weak adhesion and easy detachment. Our hot melt adhesive uses a special formula that can penetrate the fiber layer of cardboard/white card, forming a tight molecular bond and increasing the bonding strength by more than 50% compared to traditional adhesives. Whether it is white card color printing packaging boxes in the electronics industry (which need to balance aesthetics and firmness) or thick cardboard packaging boxes in the home furnishing industry (which need to carry heavy items), hot melt adhesive can achieve uniform bonding without glue marks overflowing, ensuring firmness without affecting the appearance of the cardboard box. 4. Excellent weather resistance, suitable for various storage environments

Large cardboard boxes in industries such as electronics, home furnishings, and appliances often need to be stored in different temperature and humidity environments (such as high-temperature warehouses in summer and humid environments in rainy seasons). Traditional adhesives are prone to moisture softening and high temperature failure. The hot melt adhesive for large cardboard boxes can maintain stable performance in a wide temperature range of -30 ℃ to 80 ℃. The adhesive layer does not absorb moisture or peel off in humid environments, and does not soften or deform in high temperature environments. For example, in the outdoor storage cardboard boxes of the electrical industry, even after experiencing rainy seasons and exposure to sunlight, hot melt adhesive can still maintain its bonding strength, avoiding packaging failure caused by environmental changes.

2、 The core application of hot melt adhesive in large cardboard boxes in various industries

1. Electronics industry: Ensuring the transportation safety of precision products

Large packaging boxes for electronic products (such as computers and mobile phone accessories) often use white cardboard and corrugated paper composite materials, which require high flatness and firmness of bonding. The rapid curing characteristics of hot melt adhesive are suitable for high-speed packaging lines in the electronics industry. Its strong adhesion ensures that the cardboard box does not scatter during transportation, avoiding collision damage to internal precision components; The excellent adhesion of the self card ensures a smooth appearance of the packaging box and does not affect the brand image.

2. Beverage industry: adapting to high-speed turnover needs

Large turnover boxes in the beverage industry, such as bottled water and carbonated beverage boxes, require repeated use and are often exposed to humid environments. The weather resistance of hot melt adhesive can cope with damp storage and cold chain transportation scenarios, avoiding cardboard boxes from getting damp and opening glue; The fast curing characteristic is suitable for high-speed sealing lines of dozens of containers per minute, meeting the demand for "fast production and fast turnover" in the beverage industry. At the same time, the strong adhesion can ensure that the turnover boxes remain firm after multiple loading and unloading.

3. Home and appliance industry: carrying heavy objects without delamination

Large cardboard boxes for home furnishings (such as furniture and textiles) and electrical appliances (such as refrigerators and washing machines) need to bear heavy weight and have long transportation distances. The strong adhesion of hot melt adhesive to cardboard and thickened corrugated paper ensures that the seams of the cardboard box can withstand heavy pressure without cracking; The weather resistance is adapted to the temperature and humidity changes during cross regional transportation, avoiding the opening of cardboard boxes in low-temperature or humid environments in the north or south, and ensuring the safe delivery of products. 3、 The actual value of hot melt adhesive in the large cardboard box industry

3、 The actual value of hot melt adhesive in the large cardboard box industry

1. Improve packaging efficiency and reduce labor costs

Rapid curing characteristics are suitable for automated sealing equipment, reducing manual waiting time for drying. The sealing line, which originally required 2 people to operate, can be completed by 1 person after using hot melt adhesive, reducing labor costs by 30%; At the same time, there is no need to set up additional drying processes, saving factory space and energy consumption, further reducing production costs.

2. Reduce transportation losses and lower after-sales costs

The strong adhesion and weather resistance properties make large cardboard boxes less likely to open or break apart during transportation and storage. The product transportation loss rate has decreased from 5% -8% of traditional adhesives to less than 1%, significantly reducing product damage and replenishment costs caused by packaging failure. At the same time, it reduces customer complaint rates and maintains the manufacturer's brand reputation.

3. Simplify process operations and adapt to multi category production

Hot melt adhesive does not require complex surface treatment for cardboard and white cardboard, and can be directly used for bonding large cardboard boxes of different materials and specifications; Whether it is small batch customized cardboard boxes in the electronics industry or large batch standard cardboard boxes in the beverage industry, they can stably produce results, and manufacturers do not need to frequently replace adhesives or adjust equipment parameters, improving production flexibility. Conclusion

Conclusion

Large cardboard packaging in the electronics, beverage, home, and electrical industries requires extremely high efficiency, firmness, material adaptability, and weather resistance. Hot melt adhesive, with its advantages of rapid curing, strong adhesion, significant adhesion to cardboard/white cards, and excellent weather resistance, perfectly solves the pain points of traditional adhesives. As a professional hot melt adhesive manufacturer, we can provide customized hot melt adhesive products based on different industries' carton materials (such as cardboard, white cardboard, corrugated paper) and packaging processes, helping carton manufacturers improve efficiency, reduce costs, ensure quality, and gain an advantage in market competition.