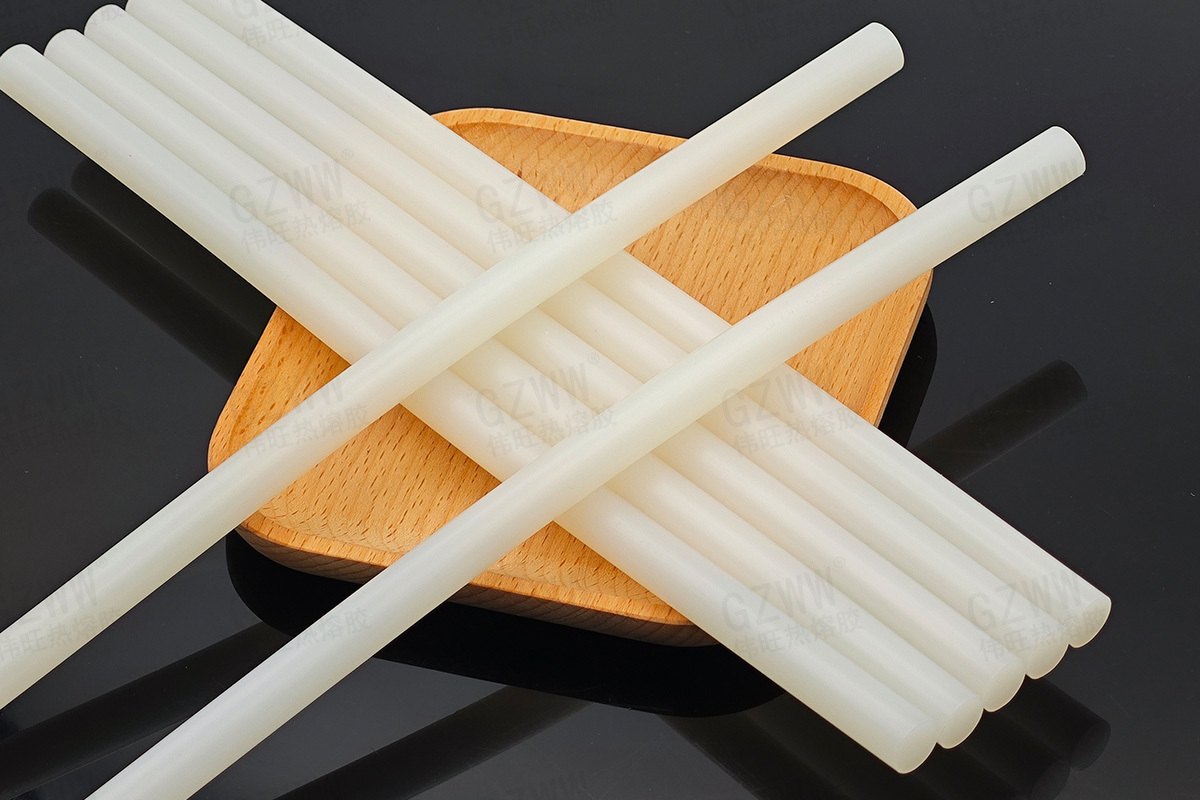

New choice for automotive interior processing and bonding: how hot melt adhesive ensures interior quality and production efficiency

Classification: Company News

Classification: Industry Information

2025-09-10

In the field of automotive interior processing, the reliability of the bonding process directly affects the durability, safety, and aesthetics of the interior, from the fixation of sound-absorbing cotton to the bonding of the car roof, and then to the assembly of the door interior panel. PP material (polypropylene) is commonly used in automotive interiors. Traditional adhesives often face problems such as weak adhesion, slow curing, poor high temperature resistance, and insufficient initial adhesion. However, hot melt adhesives specially developed for automotive interiors are becoming an efficient solution for automotive interior manufacturers due to their fast curing, strong adhesion, significant adhesion to PP materials, excellent high temperature resistance, and core advantages of good initial adhesion and holding strength.

1、 The core advantage of automotive interior hot melt adhesive: precise matching of interior processing requirements

1. Fast curing, speeding up production pace

After being heated and melted, hot melt adhesive can solidify and shape in just a few seconds when in contact with automotive interior materials, without the need to wait for a long drying time like traditional adhesives. In the bonding process between sound-absorbing cotton and car body sheet metal, it can keep up with the running rhythm of the automated production line and avoid the displacement of sound-absorbing cotton caused by the glue not drying yet; When batch bonding car roofs, rapid curing can reduce the accumulation of semi-finished products, increase single batch production efficiency by more than 40%, easily meet the production needs of the automotive industry for large quantities and fast delivery, and break the production capacity bottleneck caused by slow curing of traditional adhesives.

2. Strong adhesion and excellent initial adhesion, ensuring stable and durable interior

The hot melt adhesive has excellent adhesion to PP, non-woven fabric, leather, foam cotton and other materials commonly used in automobile interiors, and also has good initial adhesion and adhesion retention - the initial adhesion performance ensures the instant positioning of the materials after fitting, without the need for additional fixtures, can withstand the temperature changes and slight pulling in daily use, avoid bulging and falling off caused by poor adhesion, significantly improve the durability of automobile interiors, and reduce after-sales repair problems.

3. Significant adhesion to PP material, solving the pain points of difficult adhesion

PP material has always been a difficult point in bonding automotive interiors due to its low surface tension and weak polarity. Our hot melt adhesive uses a special modified formula that can effectively penetrate the surface of PP material, forming a strong intermolecular bond. The bonding strength is increased by more than 50% compared to traditional adhesives, and it can tightly adhere to PP material in the initial bonding stage without waiting for curing before entering the next process. Whether it is the bonding of PP auto roof substrate and foam layer, or the bonding of PP interior panel and foam cotton, it can achieve stable connection, without complex surface pretreatment of PP material (such as polishing, primer coating), and simplify the processing process.

4. Excellent high temperature resistance and adaptability to the interior environment of vehicles

When the car interior is exposed to direct sunlight in summer, the temperature inside the car can reach over 80 ℃. Traditional adhesives are prone to softening and flowing, causing the interior to peel off. Automotive interior hot melt adhesive can maintain stable performance in a wide temperature range of -40 ℃ to 120 ℃. The adhesive layer does not soften or fail in high temperature environments, and does not become brittle or crack in low temperature environments. Moreover, the adhesive strength can remain stable even at extreme temperatures. Even in high-temperature areas near the engine compartment or in harsh winter environments in the north, it can ensure stable adhesion of the interior, meeting the strict standards of the automotive industry for interior weather resistance. 2、 Core application scenarios of hot melt adhesive in automotive interior processing

2、 Core application scenarios of hot melt adhesive in automotive interior processing

1. Acoustic cotton bonding: noise reduction and stability

Car body sheet metal, roof, and interior of doors need to be pasted with sound-absorbing cotton to reduce driving noise. The strong adhesion and good initial adhesion of hot melt adhesive can instantly fix the sound-absorbing cotton after bonding, avoiding uneven noise reduction caused by displacement after bonding; The advantages of high temperature resistance and adhesive strength prevent the displacement and opening of sound-absorbing cotton in high-temperature environments, maintaining good noise reduction effect and improving driving comfort.

2. Car roof fitting: flat and durable

2. Car roof fitting: flat and durable

The car roof is composed of PP substrate, foam buffer layer, fabric or leather skin and other multi-layer materials, which requires high smoothness and stability of bonding. The excellent adhesion and initial adhesiveness of hot melt adhesive to PP material can immediately position the various layers of the ceiling material after bonding, avoiding wrinkles and bulges during the bonding process, and allowing for subsequent cutting and assembly without waiting for curing; The adhesive strength and high temperature resistance ensure that the roof does not peel or deform during long-term use, and can withstand high temperatures in summer and low temperatures in winter, ensuring a smooth appearance of the roof and enhancing the overall texture of the car interior.

3. Assembly of interior door panels: exquisite and durable

3. Assembly of interior door panels: exquisite and durable

The door interior trim panel is spliced from PP substrate, foam cotton, leather and other materials. The initial adhesion of hot melt adhesive can allow different materials to be quickly fixed after splicing to ensure that the edges do not shift during assembly and ensure the flatness of the interior trim panel; Strong adhesion and holding force achieve long-term stable bonding, avoiding glue cracking and edge warping during use; The high temperature resistance performance keeps the interior panel intact under the vibration of door opening and closing and high temperature environment, balancing aesthetics and durability, and enhancing the overall texture of the car interior.

3、 The actual value of hot melt adhesive in the automotive interior industry

1. Improve interior quality to meet industry standards

The strong adhesion and high temperature resistance characteristics of hot melt adhesive, as well as the dual advantages of initial adhesion and holding, enable automotive interiors to withstand long-term vibration, high temperature, and friction, avoiding problems such as glue cracking, displacement, and rework caused by insufficient initial adhesion due to traditional adhesives; The excellent adhesion of PP material solves the difficult sticking pain points in interior processing, helping manufacturers produce interior products that meet the strict standards of automotive OEMs and enhance market competitiveness.

2. Optimize production processes and reduce overall costs

Rapid curing and good initial adhesion are compatible with automated production lines, and there is no need for additional fixtures for initial adhesion positioning, reducing manual waiting time and equipment occupation costs; No need for complex pre-treatment of PP material or additional drying process, saving processing steps and energy consumption; Strong adhesion and holding force can reduce the rework rate caused by interior glue cracking and displacement, reduce material waste, and overall help enterprises reduce production costs by 15% -20% and increase profitability.

3. Simplify process operations and adapt to diverse needs

The application process of hot melt adhesive is simple and compatible with various processes such as automated dispensing and rolling of automotive interiors. The excellent characteristics of initial adhesion, holding and bonding enable stable performance under different processes; Whether it is the interior processing of small batch customized car models or the standardized production of large batch mass-produced car models, it can be quickly adapted; Simultaneously compatible with various interior materials such as PP, non-woven fabric, leather, etc., manufacturers do not need to frequently replace adhesives, simplify process debugging and inventory management, and enhance production flexibility. Conclusion

Conclusion

The processing of automotive interiors requires extremely high efficiency, strength, material adaptability, and weather resistance for bonding. Hot melt adhesive, with its fast curing, strong adhesion, significant adhesion to PP materials, high temperature resistance, and good initial and holding properties, perfectly solves the pain points of traditional adhesives. As a professional hot melt adhesive manufacturer, we can provide customized hot melt adhesive products based on the material characteristics (such as PP substrate, sound-absorbing cotton, leather) and process requirements of automotive interiors, helping automotive interior manufacturers improve production efficiency and product quality, and gain an advantage in market competition.