Traditional glue doesn't stick firmly? Shoe material, luggage folding, heat exchange adhesive: suitable for both leather and fabric, doubling efficiency

Classification: Company News

Classification: Industry Information

2025-09-03

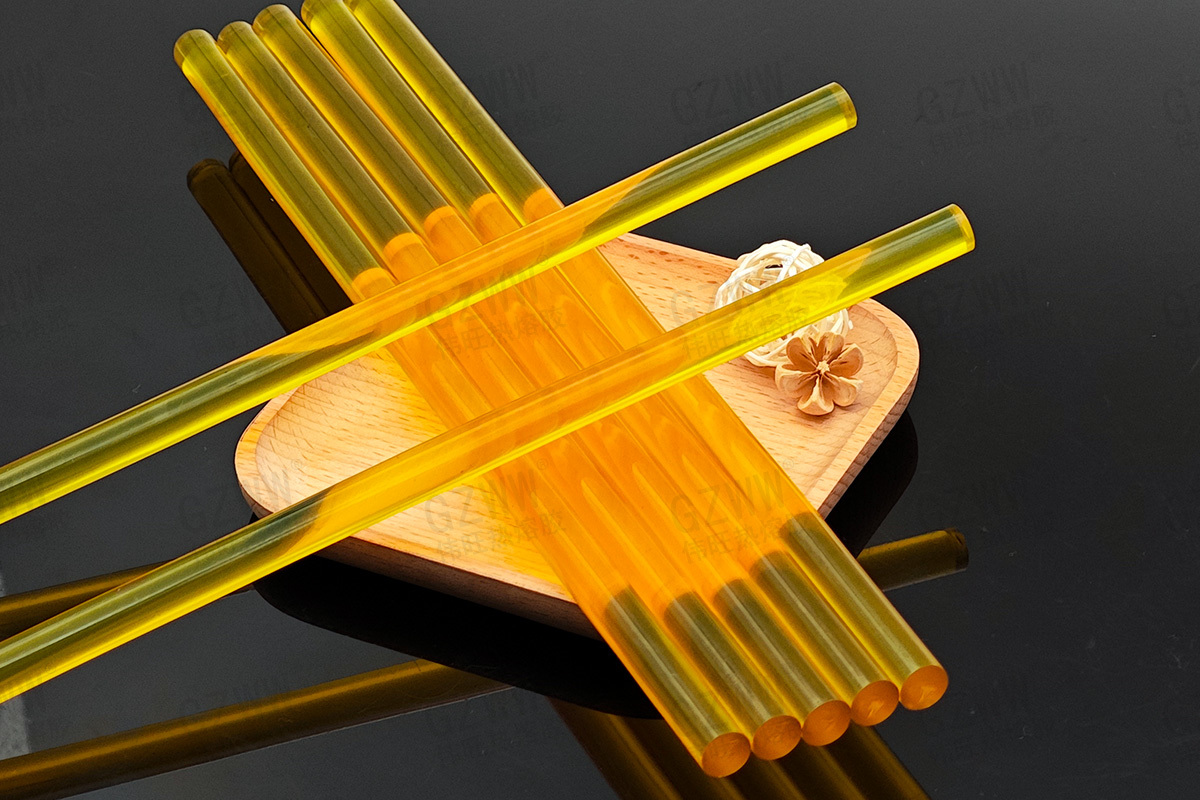

In the field of shoe materials and luggage manufacturing, the folding process is a key link that determines the delicacy and durability of product appearance - from the edge shaping of leather shoe uppers to the edge bonding of canvas bags and leather bags, the bonding effect directly affects the texture and service life of shoes and bags. Traditional folding adhesives often face problems such as slow curing, weak adhesion, and poor adaptability to leather fabrics. However, hot melt adhesives specially developed for folding shoe materials and bags, with their core advantages of fast curing, strong adhesion, and significant adhesion to leather fabrics, are becoming an efficient solution for shoe and bag manufacturers.

1、 The core advantage of hot melt adhesive for shoe material and luggage folding: precise matching of folding process requirements

1. Fast curing, speeding up production pace

After being heated and melted, hot melt adhesive can solidify and shape shoe packaging materials such as leather and fabric in just a few seconds, without the need to wait for dozens of minutes to dry like traditional adhesives. In the process of folding leather shoe uppers, it is possible to keep up with the operating rhythm of automated folding equipment and avoid edge displacement caused by wet glue; When folding bags and suitcases over a large area, rapid curing can reduce the accumulation of semi-finished products, increase the production efficiency of a single batch by more than 35%, easily cope with the high demand for large orders in the shoe and bag industry during peak seasons, and break the production capacity bottleneck caused by slow curing of traditional adhesives.

2. Strong adhesion ensures stable and durable folding

Hot melt adhesive has excellent adhesion to commonly used materials such as genuine leather, synthetic leather, canvas, nylon cloth, etc. for shoe bags, and can form a tight and long-lasting bonding effect. After the leather shoes are folded, even if they are worn for a long time and subjected to bending and friction, the edges will not have glue peeling or curling; After the edges and corners of the luggage are folded and attached, it can withstand the pulling and collision during daily use, avoiding edge cracking caused by weak bonding, significantly improving the durability of the shoe bag product, and reducing after-sales repair problems.

3. Suitable for leather fabric, with significant bonding effect

Based on the material characteristics of leather and fabric, hot melt adhesive adopts a special formula design, which can firmly adhere to the fiber layer of the leather surface without damaging the soft texture of the fabric. Smooth artificial leather folding can avoid surface whitening caused by adhesive layer penetration; For the folding of lightweight canvas and nylon fabric, it can achieve uniform adhesion without producing a stiff feeling, ensuring that the folding of the shoe bag is both stable and conforms to the characteristics of the material itself, balancing practicality and aesthetics.

2、 The core application scenarios of hot melt adhesive in shoe materials and luggage folding

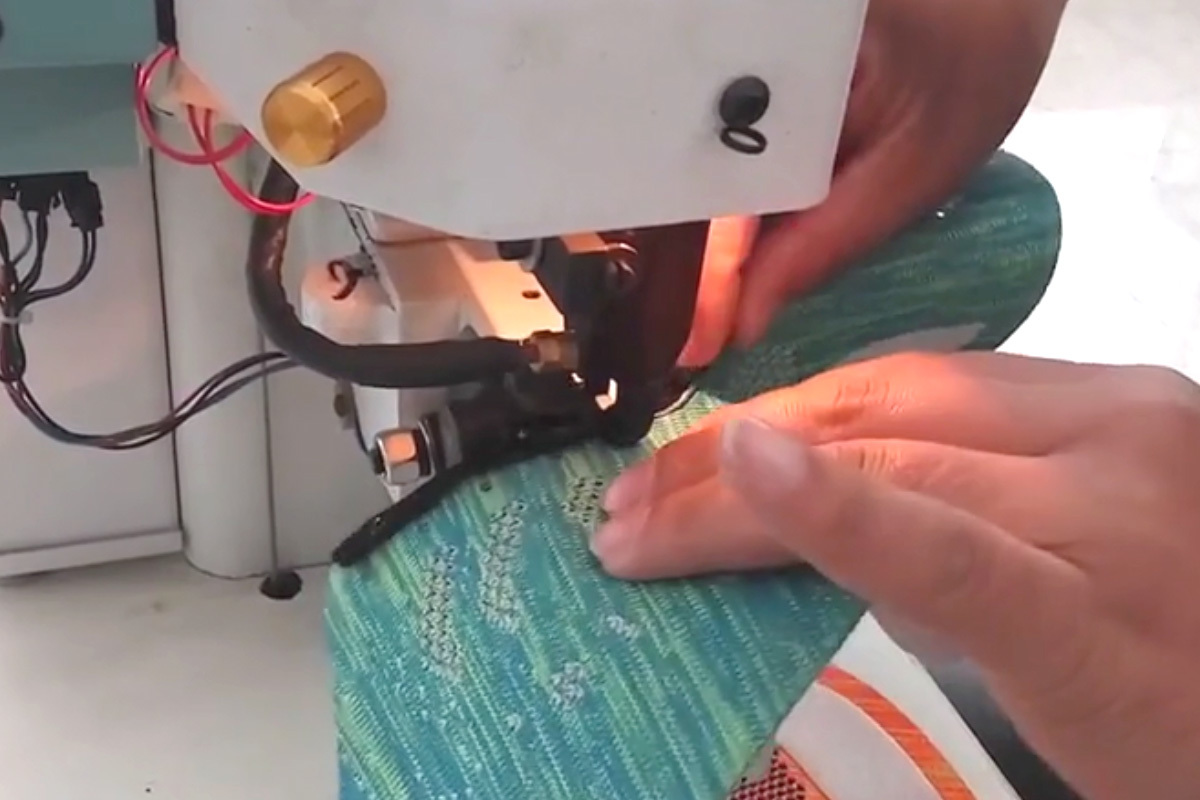

1. Shoe material folding: Suitable for various shoe types, ensuring the texture of the shoe upper

In the production of shoes such as leather shoes, casual shoes, and sports shoes, hot melt adhesive can adapt to the folding of shoe uppers of different materials - when folding leather shoes, strong adhesion can ensure that the edges are shaped and flat; When folding canvas casual shoes, the fabric fibers will not be damaged, maintaining the softness of the shoe upper; When the mesh fabric and synthetic leather of sports shoes are spliced and folded, they can meet the bonding requirements of both materials, avoiding glue cracking caused by material differences, making the upper both exquisite and durable.

2. Luggage folding: Covering multiple types of luggage, enhancing the delicacy of edges and corners

Whether it's genuine leather bags, synthetic leather bags, canvas bags, or nylon bags, hot melt adhesive can adapt to the folding process. The corners of the genuine leather bag are folded, and after bonding, the edge lines are smooth without any visible glue marks, enhancing the luxury grade texture; The opening and side folds of the canvas bag are highly adhesive and do not affect the breathability of the fabric, ensuring that it is not easily deformed during daily use; The PVC and EVA material of the luggage shell is folded, and hot melt adhesive can cope with the toughness characteristics of the material, avoiding cracking at the folded edge due to vibration, and balancing aesthetics and durability.

3、 The actual value of hot melt adhesive in the shoe material and luggage industry

1. Improve product quality and enhance market competitiveness

The strong adhesive properties of hot melt adhesive make the folded edges of shoe bags more stable and durable, avoiding the problems of glue opening and curling caused by traditional adhesives; The excellent adaptability of leather fabrics ensures a smooth and exquisite appearance of folded edges, without glue marks or damage, helping manufacturers produce shoe and bag products that meet the needs of the mid to high end market, winning recognition from brand customers and consumers, and standing out in homogeneous competition.

2. Optimize production processes and reduce overall costs

Rapid curing characteristics adapt to automated folding production lines, reducing manual waiting time and equipment occupation costs; No need to set up additional drying processes, saving factory space and energy consumption; Strong adhesion can reduce the rework rate caused by edge bending and glue opening, reduce material waste, and overall help enterprises reduce production costs by 12% -18% and increase profitability.

3. Simplify process operations and adapt to diverse production needs

The hot melt adhesive application process is simple, without the need for complex surface pretreatment of leather fabrics, and can be directly used for edge bonding of different materials; Whether it is the fine folding of small batch customized shoe bags or the standardized folding of large batch production, they can all achieve stable results. Manufacturers do not need to frequently replace glue for different materials, simplifying process debugging and inventory management, and improving production flexibility.

Conclusion

The folding process of shoe materials and luggage requires extremely high efficiency, strength, and material compatibility for bonding. Hot melt adhesive, with its advantages of rapid curing, strong adhesion, and significant adhesion to leather fabrics, perfectly solves the pain points of traditional adhesives. As a professional hot melt adhesive manufacturer, we can provide customized hot melt adhesive products based on the material characteristics (such as genuine leather, canvas, synthetic leather) and process requirements of shoe bag folding, helping shoe bag manufacturers improve production efficiency and product quality, and gain an advantage in market competition.