When binding books and periodicals, choose the right glue to ensure a firm bond and prevent pages from coming off, doubling production efficiency

Classification: Company News

Classification: Industry Information

2025-07-30

In the field of book and periodical production and binding, from thick tender documents to exquisite picture albums, from commonly used books and periodicals to best-selling magazines, the firmness, aesthetics and efficiency of binding directly affect product quality and production benefits. The back adhesive and edge adhesive hot melt adhesive specially developed for books and periodicals, with its odorless, non-fringing, rapid curing, strong adhesion and excellent bonding effect on various types of paper, is becoming an efficient solution for book and periodical manufacturers and binding factories.

I. Core advantages of hot melt adhesive for books and periodicals: It meets the binding needs of various types of books and periodicals

I. Core advantages of hot melt adhesive for books and periodicals: It meets the binding needs of various types of books and periodicals

Strong adhesion and greater firmness: It has excellent adhesive force on various types of paper such as coated paper, offset paper, and special paper. It can closely bond the pages to the spine and edges of the book. Even for tender documents and picture albums with many pages and large thickness, it can be firmly fixed. Long-term flipping does not cause the pages to fall apart or drop, solving the problem of insufficient adhesive force of traditional glue.

Fast curing improves efficiency: After heating and melting, it comes into contact with the paper and cures in a short time without the need for a long wait. Compared with the drying time of traditional glue, it can increase the binding efficiency by more than 40%, adapt to the rhythm of batch production in the book and periodical industry, and meet the order demands during peak seasons.

Odorless and more environmentally friendly: Made from eco-friendly base materials, it contains no volatile harmful components. There is no odor after gluing and binding, which will not pollute the paper and will not affect the reading experience, meeting the environmental protection requirements for book and periodical printed materials.

No stringing, neat and tidy: The special formula design ensures that the glue breaks smoothly during the application process, leaving no glue residue. This prevents glue from adhering to the surface of the book pages or spines, affecting the appearance. It eliminates the trouble of manual cleaning and guarantees a neat and exquisite appearance of the books and periodicals.

Compatible with various types of paper: Whether it is smooth coated paper, thick card paper, or thin newsprint, it can achieve stable bonding. It is compatible with the paper characteristics of different types of publications such as tender documents, books, magazines, and picture albums, without the need to frequently change the glue.

Ii. The Actual Value of Hot melt Adhesive in the Book and Periodical Industry

Enhance binding quality: Strong bonding ensures that books and periodicals can withstand long-term reading and preservation. A clean appearance free from glue thread contamination enhances the product grade, helps manufacturers create high-quality books and periodicals, and strengthens market competitiveness.

Improving production efficiency: Rapid curing shortens the time of the binding process, enabling the production line to complete batch orders more quickly, reducing waiting and accumulation, and allowing manufacturers to be more composed when facing urgent orders.

Reduce comprehensive costs: The absence of brushing reduces the cost of manual cleaning, and the strong adhesion lowers the rework cost caused by loose pages. Long-term use can save a considerable amount of expenses for enterprises.

Expand application scenarios: The odorless feature of hot melt adhesive makes it suitable for all kinds of books and periodicals, including children's books, textbooks and other publications with high environmental protection requirements, helping manufacturers expand into more business areas.

Third, it is widely adaptable to various scenarios and meets diverse needs

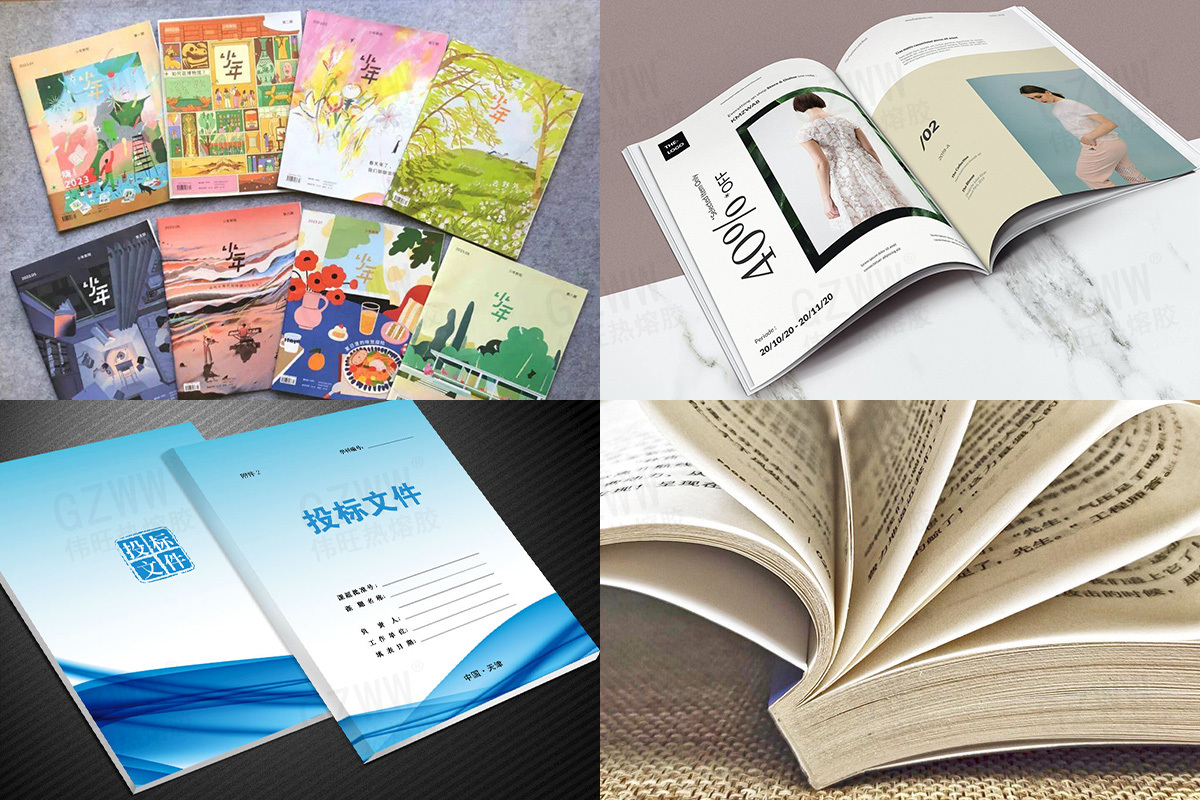

Tender document binding: Tender documents have many pages and are thick, which requires high binding firmness. The strong adhesion of hot melt adhesive can ensure that the tender documents remain intact for a long time, with a neat appearance and a professional image.

Books, periodicals and magazines: Mass-produced books, periodicals and magazines require efficient binding methods. The rapid curing feature of hot melt adhesive can increase production capacity, while the advantages of no odor and no stringing ensure the reading experience and appearance quality.

Album production: Albums often use smooth paper such as coated paper. The excellent bonding effect of hot melt adhesive on this type of paper can make the page numbers of the album neat and not fall off, enhancing the artistic presentation effect.

Conclusion

Hot melt adhesive for the back and edge of books and periodicals, with its advantages of strong adhesion, rapid curing, no odor and no stringing, provides efficient and high-quality binding solutions for book and periodical producers and binding manufacturers. Whether it is tender documents, books, magazines or picture albums, they can all achieve a firm, neat and environmentally friendly binding effect through hot melt adhesive. As a professional hot melt adhesive manufacturer, we will continue to provide suitable products to help the book and periodical industry improve quality and efficiency and gain an advantage in market competition.