A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

Classification: Company News

Classification: Industry Information

2025-06-17

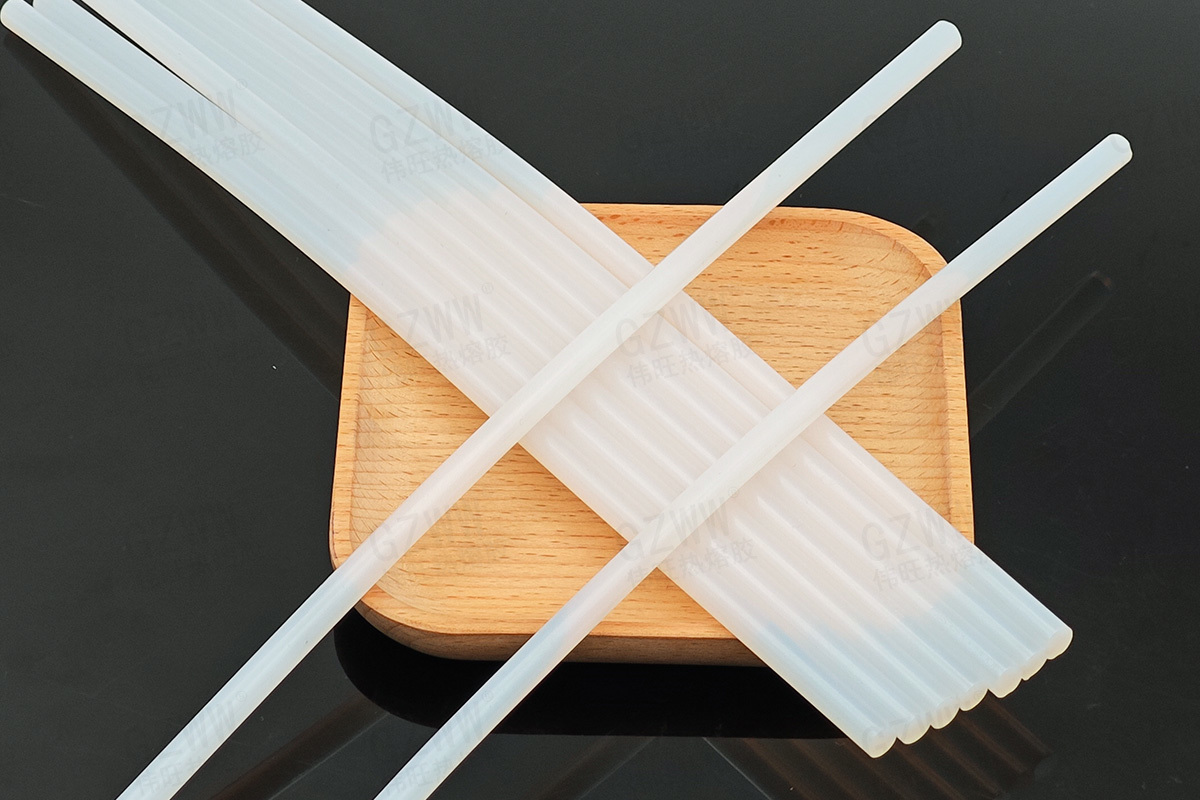

In the field of electronic wiring harness manufacturing, the reliability of terminal fixation directly affects the electrical performance and service life of the product. Traditional adhesives are gradually showing their limitations when dealing with complex working conditions, while hot melt adhesives, with their outstanding comprehensive performance, are becoming the ideal choice for electronic wire harness manufacturers.

1. Core advantages of hot melt adhesive: Specifically designed for electronic wiring harness applications

1. Excellent resistance to high and low temperatures

Hot melt adhesive can maintain stable performance in extreme environments. Whether it is outdoor equipment in the severe cold of the north or the engine compartment of a car operating at high temperatures, it can ensure that the terminal fixation points do not fall off or crack. In the face of the diverse usage scenarios of electronic devices, this stability provides reliable quality assurance for the products.

2. Rapid curing significantly enhances production efficiency

After being heated and melted, the hot melt adhesive can solidify rapidly within seconds upon contact with terminals and wire harnesses, eliminating the need for a long drying time like traditional adhesives. This feature enables the production line to operate continuously, significantly shortening the production cycle. The production efficiency of a single batch of wire harnesses can be increased by more than 50%, helping enterprises effectively reduce time costs.

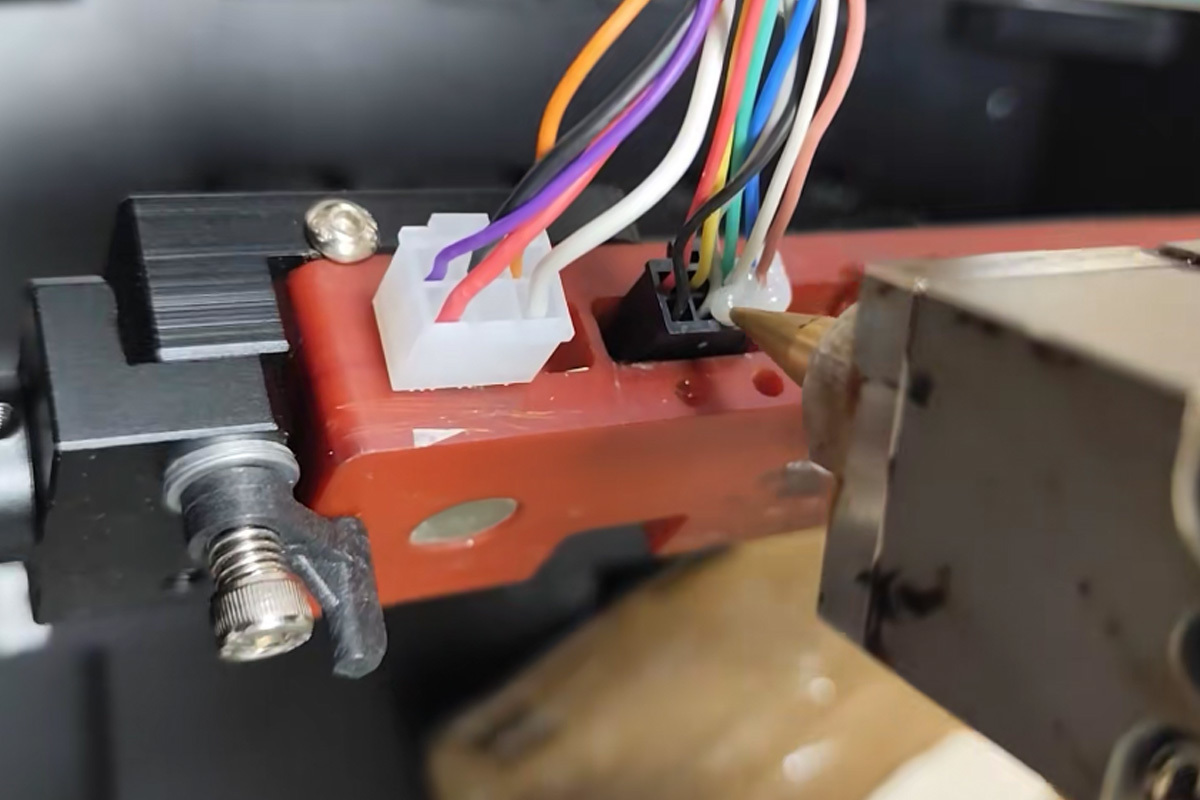

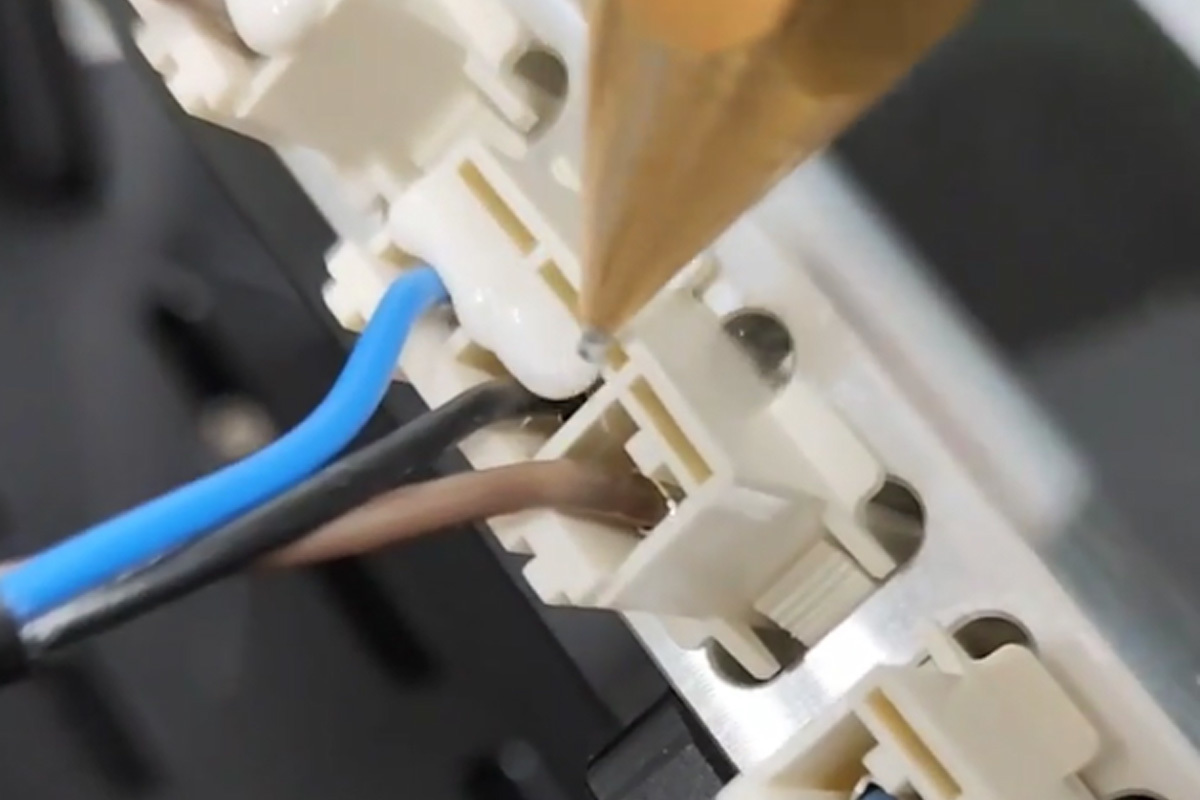

3. Super strong adhesion ensures a firm connection

Hot melt adhesive has extremely strong adhesion to different materials such as metal terminals and plastic wire harness sheaths, forming a tight wrapping and fixing effect. Even under conditions of severe vibration and frequent bending, it can ensure that the terminals and wire harnesses are always firmly connected, significantly reducing the risk of electrical faults caused by loosening and improving the product yield rate.

Ii. Limitations of Traditional Adhesives: Multiple Predicaments of efficiency, performance and cost

The curing process is slow and the production efficiency is limited

Traditional glue takes a long time to dry, especially during mass production, which requires a dedicated waiting area and time, seriously affecting the production rhythm. Some adhesives even take several hours or even a whole day to fully cure, which greatly reduces the production capacity and delivery efficiency of enterprises.

2. Poor weather resistance and limited application scenarios

Under complex environments such as high and low temperatures and high humidity, the bonding performance of traditional adhesives will significantly decline, leading to problems such as delamination and embrittlement. This makes it difficult for electronic wiring harnesses fixed with traditional glue to meet the demands of industries such as automobiles and aerospace, which have high requirements for environmental adaptability, and increases the after-sales maintenance costs of the products.

3. The composition is complex and poses safety risks

Many traditional glues contain organic solvents and harmful chemicals. During the production process, they release pungent odors, which not only endanger the health of operators but also pose safety risks due to their flammable and explosive properties. Meanwhile, the environmental friendliness of this type of glue is difficult to meet the standards and does not conform to the current trend of green production and regulatory requirements.

Iii. The Practical Value of Hot Melt Adhesive in the Fixation of Electronic Wiring Harness Terminals

Optimize the production process and reduce the overall cost

The rapid curing property of hot melt adhesive reduces the waiting time for manual labor and the cost of equipment occupation. Combined with automated dispensing equipment, it can achieve precise dispensing and effectively reduce the waste of glue. In addition, its stable performance reduces the rate of defective products and rework, helping enterprises lower their overall production costs in multiple aspects.

2. Enhance product competitiveness and expand market space

With the excellent weather resistance and reliability of hot melt adhesives, electronic wiring harness products can meet the demands of more high-end and complex application scenarios, helping enterprises gain recognition from customers in the automotive, communication, new energy and other industries, and laying a foundation for exploring high-value-added markets.

3. Green and environmentally friendly, in line with industry trends

Hot melt adhesives contain no solvents and no harmful volatile substances, and comply with international environmental protection standards such as RoHS and REACH. The use of hot melt adhesive not only enhances a company's environmental image but also avoids the risk of order loss due to non-compliance with environmental standards, thereby strengthening the company's sustainable development capabilities.

Conclusion

Under the continuous pursuit of high efficiency, stability and environmental protection in the electronic wire harness manufacturing industry, hot melt adhesive, with its outstanding advantages such as resistance to high and low temperatures, rapid curing and strong adhesion, has become an innovative solution for terminal fixation. As a professional hot melt adhesive manufacturer, we are committed to providing customized hot melt adhesive products and technical support for electronic wire harness manufacturing enterprises, helping them enhance production efficiency, optimize product quality, and stand out in the fierce market competition.

RELATED INFORMATION

This article focuses on the pain points in the production of electronic wiring harnesses and analyzes the core advantages of hot melt adhesives: resistance to high and low temperatures, efficiency improvement through curing in seconds, and strong adhesion. Compared with traditional adhesives that cure slowly, have poor weather resistance and pose potential risks, hot melt adhesives help enterprises reduce costs, improve quality and expand markets. They comply with environmental protection standards such as RoHS and are the preferred choice for wire harness fixation.

View Details