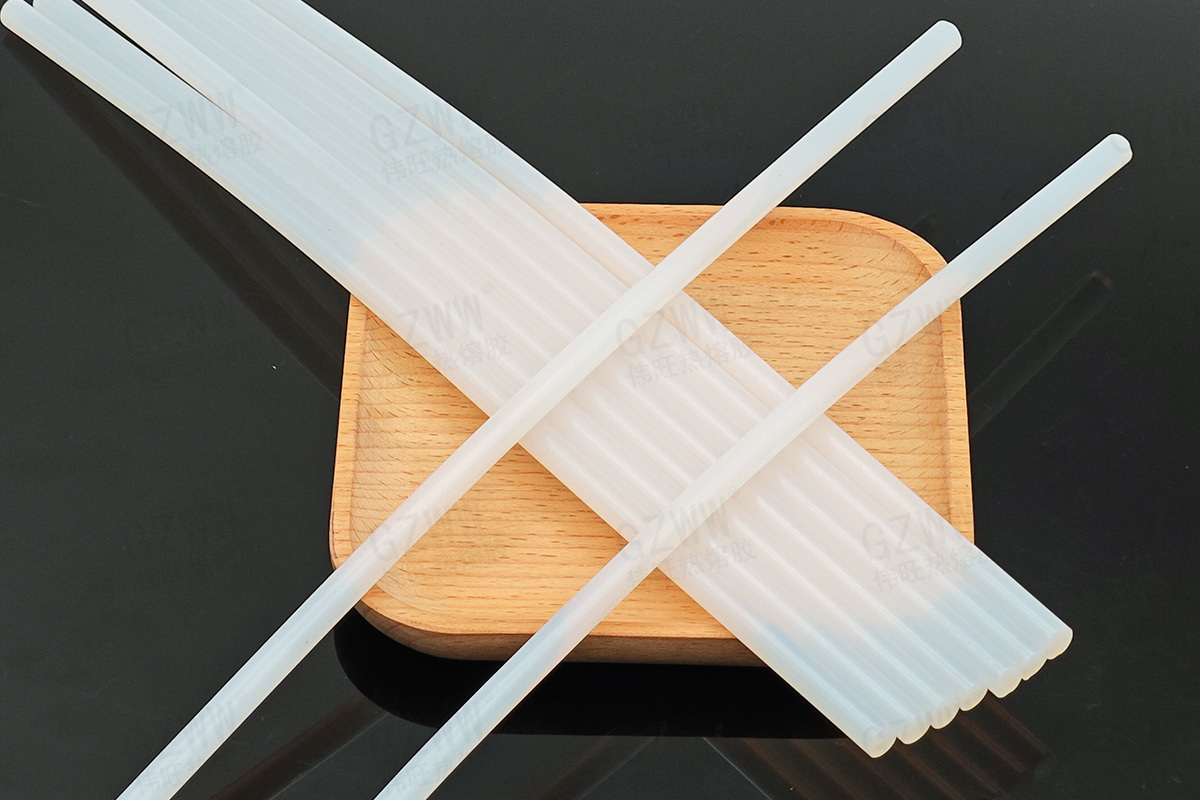

Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

Classification: Company News

Classification: Industry Information

2025-06-04

In various production and manufacturing scenarios, especially in fields such as production lines that require manual bonding, handicraft making, and small component assembly, traditional adhesives often have problems such as slow drying, weak adhesion, and cumbersome operation, resulting in low production efficiency and unstable product quality. In response to these pain points, we have launched a dedicated hot melt adhesive stick for manual bonding. With core advantages such as high adhesion, rapid curing, easy operation, and environmental friendliness and safety, we provide manufacturers and purchasers with a more superior bonding solution.

I. Core Features: Deeply adapted to manual bonding requirements

Super strong adhesion, firm and long-lasting

Adopting a high-molecular polymerization formula, the hot melt adhesive stick can quickly penetrate and closely adhere to the surfaces of various materials such as paper, wood, plastic, fabric, and metal after melting. Whether it is the fine component assembly of handicrafts or the fixation of small components of industrial products, it can provide strong and long-lasting adhesive force, significantly reducing the defective rate caused by delamination.

2. Rapid curing, improving efficiency

Just pair it with a regular hot melt glue gun, heat it for a few seconds and it will melt and be applied. After coming into contact with the material, it will instantly solidify and take shape, without the need to wait for a long drying time like traditional glue. This feature of immediate bonding and fixation greatly simplifies the manual bonding process, significantly enhances the operational efficiency of the production line, helps enterprises shorten the delivery cycle, and enables them to handle urgent orders with ease.

3. Precise control and flexible operation

The hot melt adhesive stick has a uniform and controllable glue output. The small glue gun's glue outlet makes it convenient for operators to precisely apply dots and lines. Even the bonding requirements of complex shapes and narrow Spaces can be easily met. Whether it is standardized operations in mass production or fine operations in personalized customization, ideal bonding effects can be achieved, reducing glue waste and rework costs.

4. Environmentally friendly and safe, use with confidence

Produced strictly in accordance with environmental protection standards, it contains no toxic or harmful substances and does not release any irritating odors during heating and use. The finished products have passed SGS certification, REACH certification, etc., meeting various safety testing requirements. They are especially suitable for industries with high safety requirements such as toys, stationery, and food packaging, helping enterprises avoid environmental risks and creating a healthy working environment for operators at the same time.

Second, compared with traditional adhesives: Achieving comprehensive leadership in four major dimensions

Traditional adhesives (such as white latex glue, instant glue, etc.) have many drawbacks in manual bonding scenarios: The drying time of white latex glue can be several hours or even longer, seriously slowing down the production progress; Although instant glue cures quickly, its adhesive force is unstable and it has strict requirements for the material. Some glues contain a large amount of volatile organic solvents, which not only endanger human health but also may lead to the return of products due to non-compliance with environmental protection standards. In addition, traditional glue is prone to overflow and flowing during application, increasing the cleaning cost and time cost.

Our special hot melt adhesive sticks for manual bonding effectively solve these problems: the combination of high adhesion and rapid curing increases production efficiency by more than 60%. The environmental protection and safety features help enterprises pass various strict quality inspections and expand the market. The precise and controllable operational performance reduces glue waste and lowers the overall usage cost. The wide material compatibility is suitable for almost all manual bonding requirements, avoiding production risks caused by improper selection of glue.

Iii. Empowering Industries: Value Upgrading in Multiple Fields

For handicraft manufacturers, the precise bonding and traceless characteristics of hot melt adhesive sticks can perfectly present the exquisite details of handicrafts, enhancing the product grade and market competitiveness. The advantage of rapid solidification helps enterprises achieve flexible production in small batches and multiple styles, and respond quickly to market trends.

In the small component assembly production line, the efficient bonding of hot melt adhesive rods significantly shortens the processing time of individual products and enhances the overall production capacity of the assembly line. Stable adhesive force ensures the consistency of product quality and reduces the rate of after-sales rework.

For industries with high safety requirements such as toys and food packaging, environmentally friendly and safe hot melt adhesive sticks can ensure that products meet national and international standards, helping enterprises win customer trust and expand domestic and international markets.

In the current era of pursuing efficient production and high-quality products, choosing a high-performance hot melt adhesive stick is the key for enterprises to enhance their competitiveness. Contact us immediately to get a customized solution and jointly embark on a new chapter of efficient, precise and environmentally friendly manual bonding!

RELATED INFORMATION

In response to the pain points of traditional adhesives in manual bonding scenarios, a dedicated hot melt adhesive stick for manual bonding has been launched. It features high adhesion, rapid curing, easy operation, environmental friendliness and safety, and can be adapted to various materials such as paper and wood, increasing production efficiency by over 60% and reducing rework and costs. It is applicable to industries such as handicrafts, assembly lines, and toy packaging.

View Details