Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

Classification: Company News

Classification: Industry Information

2025-05-26

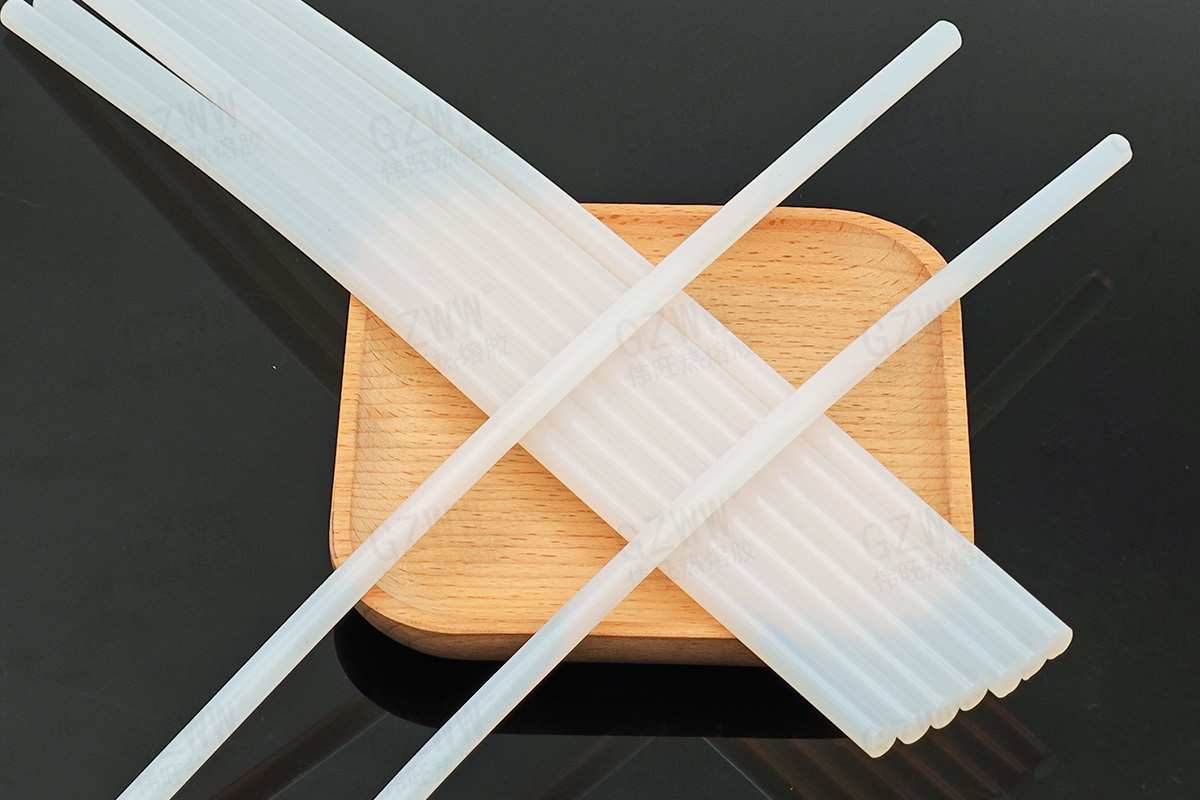

In the production of handbags and hand-held bags, traditional adhesives often encounter problems such as weak bonding, easy delamination, slow drying, and bag surface contamination, which seriously affect product quality and production efficiency. In response to the pain points of the industry, we have launched a special hot melt adhesive for handbags. With core advantages such as high adhesion, rapid curing, environmental friendliness, odorlessness, and zero residue, it has become the preferred solution for handbag manufacturers to enhance their competitiveness.

I. Core Features: Precisely match the production demands of handbags

Super strong adhesion, long-lasting and firm

With a special formula design, the hot melt adhesive can closely bond with commonly used materials for handbags such as paper, cardstock, non-woven fabric, and laminated film. Whether it is the load-bearing part of the hand strap and the bag body or the reinforcement and bonding of the bag bottom, it can provide strong adhesion. Even when the handbag is loaded with heavy objects or used for a long time, it is less likely to have delamination or breakage, effectively enhancing the durability of the product and customer satisfaction.

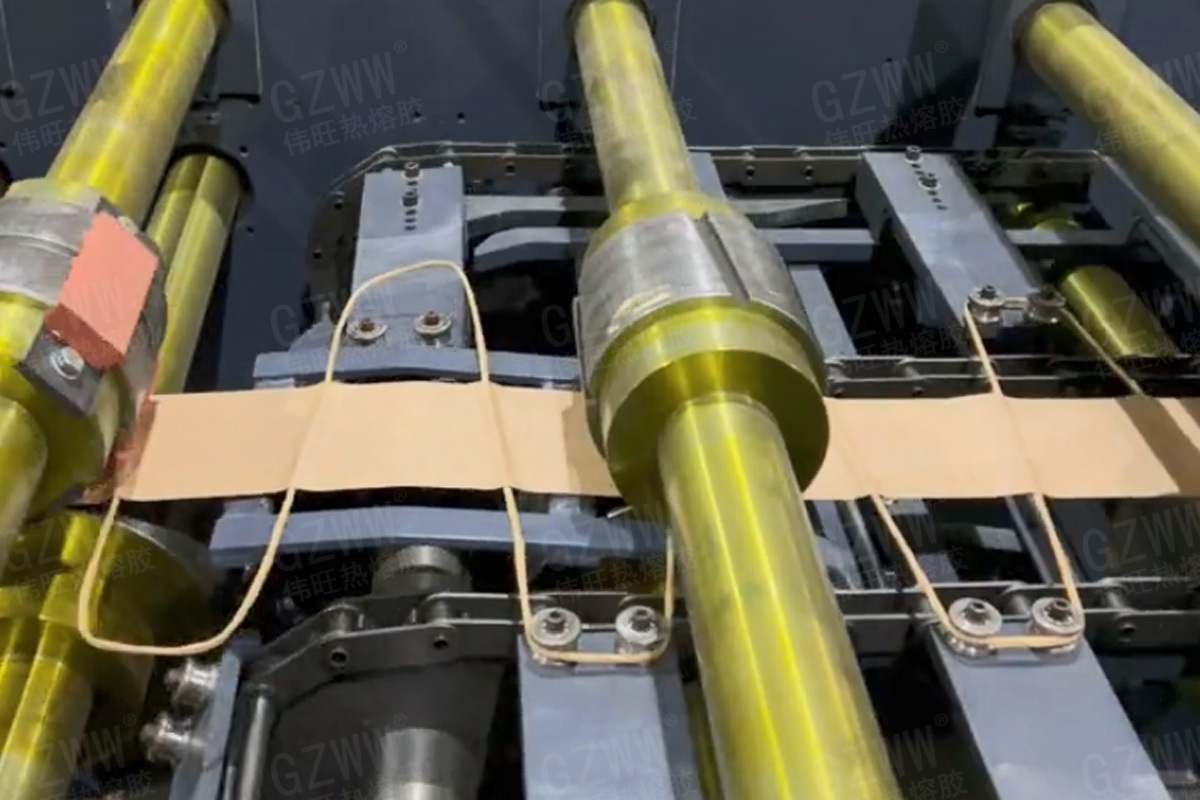

2. Rapid curing and efficient production

After being heated and melted, hot melt adhesive can quickly cure upon contact with the material. It only takes a few seconds to reach the ideal bonding strength, eliminating the need for a long drying time like traditional adhesives. This feature enables the production line to achieve high-speed continuous operation, significantly enhancing production efficiency, helping enterprises easily cope with peak order periods, and shortening the delivery cycle.

3. Environmentally friendly, odorless, safe and reliable

It is strictly produced in accordance with environmental protection standards, free of harmful chemicals and without the emission of irritating odors. During the production process, it does not pose any harm to the health of workers. The handbags made also meet the environmental protection requirements for packaging materials in the food, cosmetics and other industries, helping enterprises easily pass customer environmental protection audits and expand more high-end markets.

4. Zero residue, beautiful and traceless

The hot melt adhesive is evenly applied, with clean and neat glue breaks. There will be no problems such as stringing or glue overflow, ensuring the surface of the handbag is clean and beautiful. Even for light-colored or transparent handbags, no obvious glue marks will be left after bonding, perfectly showcasing the refinement of the packaging design and enhancing the product's grade.

Second, compared with traditional glue: Achieving comprehensive surpassing in four dimensions

Traditional adhesives (such as white latex glue and water-based glue) have many drawbacks in the production of handbags: insufficient adhesive force leads to easy damage of handbags during use; Slow drying speed seriously slows down the production rhythm and increases labor and storage costs. The harmful solvents contained not only pollute the environment, but also may prevent the product from passing environmental protection tests. In addition, problems such as glue overflow and wire drawing often require manual secondary cleaning, further reducing production efficiency.

The special hot melt adhesive for handbags effectively solves these problems: high adhesion ensures stable product quality; Rapid curing significantly enhances production efficiency; Environmental protection features help enterprises avoid environmental risks and explore more markets. The zero-residue process reduces the cost of manual cleaning and makes the production process more concise and efficient. Reduce the comprehensive usage cost and bring significant economic benefits to enterprises.

Iii. Empowering the Industry: Dual Enhancement from Quality to Efficiency

Whether it is a handbag manufacturer or a purchaser, hot melt adhesive can bring significant value. For manufacturers, the high viscosity and rapid curing properties can reduce the rate of defective products, lower rework costs, and at the same time be compatible with high-speed production lines, helping enterprises take on more orders and expand production capacity. The advantages of being environmentally friendly, odorless and having zero residue can meet the dual requirements of high-end customers for packaging quality and environmental protection, helping enterprises expand more markets and obtain higher profits. For purchasers, stable bonding quality ensures that the handbags are not easily damaged during transportation and use, effectively protecting the goods. The environmental protection features are in line with the brand image and can enhance consumers' trust. The efficiency improvement and cost optimization achieved by manufacturers through the use of hot melt tape will also be transformed into a price advantage, allowing purchasers to obtain products with higher cost performance and achieving a win-win situation for all parties.

RELATED INFORMATION

Hot melt adhesive for handbags. It features high adhesion, rapid curing, environmental friendliness, odorlessness, and zero residue. It can enhance product quality and production efficiency, simplify processes, reduce costs, and meet diverse demands.

View Details