1038/5000 New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

Classification: Industry Information

Classification: Company News

2025-04-28

In the field of EPE (Pearl Cotton) production and packaging, problems such as insufficient bonding strength, yellowing and stringing, and residual odor have long plagued enterprises. The hot melt adhesive pellets we have developed specifically for pearl cotton, with their all-scenario adaptability and environmentally friendly high performance, have become the innovative choice for pearl cotton manufacturers and packaging factories. This article will deeply analyze the core advantages of the product, helping you quickly identify the key solutions to enhance production efficiency and quality.

1. All-scenario adaptation: One rubber granule can handle all types of pearl cotton

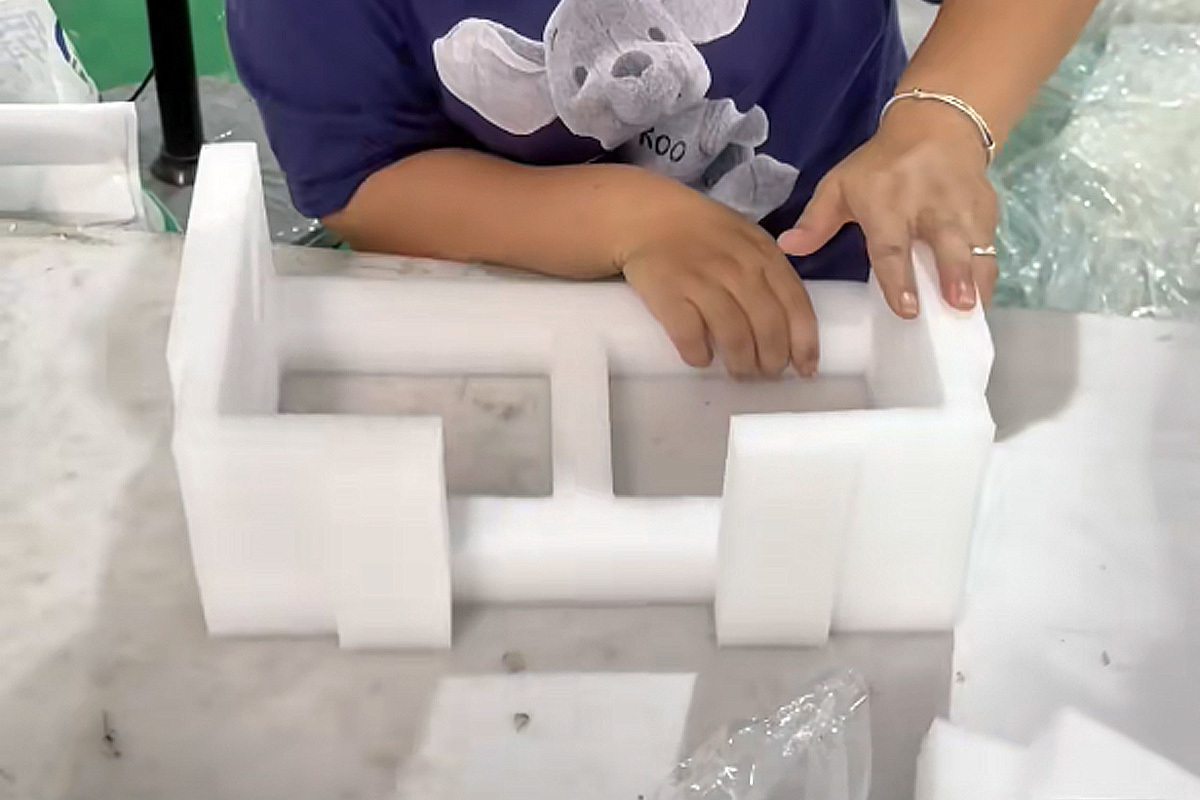

Whether it is the fine bonding of low-density pearl cotton or the thick-layer lamination of high-density pearl cotton; Whether it is the splicing of pearl cotton rolls, the bonding of special-shaped materials, or the composite process of aluminum-coated film/aluminum-coated film, pearl cotton hot melt adhesive particles can be perfectly adapted:

Material compatibility: Compatible with new materials, recycled materials, pearl cotton and various composite materials;

Process adaptability: Compatible with various hot melt equipment and supports continuous production;

Thickness adaptability: Uniform penetration and seamless bonding can be achieved from thin sheet materials to thick plate bonding. Scene test: A certain packaging factory used this rubber granule to produce cushioning inner linings for home appliances. After the drop test, there was no cracking at the bonding part, and the customer return rate decreased significantly.

Second, breakthroughs in core performance: Three major innovations - resistance to yellowing, no stringing, and no odor

① Anti-yellowing technology: Long-lasting protection of the product's appearance level

Adopting an antioxidant and weather-resistant formula, the colloid remains transparent and white even after long-term storage or exposure to light, solving the problem of traditional glue "yellowing and looking old". It is especially suitable for packaging scenarios with white or light-colored pearl cotton.

② Zero wire drawing process: Enhance the neatness of production

Unlike the drawbacks of traditional adhesives such as "dragging threads and hanging glue", the glue particles melt and have uniform fluidity. During application, the glue breaks smoothly without the need for manual cleaning of residual threads, saving equipment maintenance time and avoiding contamination of the product surface at the same time.

③ Eco-friendly formula: Odorless, more reassuring

The product has passed the EU SGS environmental protection certification, contains no harmful substances, and does not release any irritating odors during the melting process. It meets the requirements of strict scenarios such as food packaging and medical care.

Iii. Compared with Traditional Glue: Four Dimensions Revolutionize the Production Experience

Traditional pearl cotton glue often faces problems such as insufficient adhesion, poor weather resistance, low production efficiency and high comprehensive cost. For example, its initial adhesion is relatively weak, and it requires a long time of pressure setting, which is difficult to meet the demand for rapid production. It is prone to delamination and cracking under different climatic conditions, especially being susceptible to moisture during the rainy season and becoming brittle in winter. Wire drawing often occurs during operation, requiring frequent equipment cleaning, which leads to increased labor losses. In addition, traditional adhesives containing solvents have high evaporation loss and high overall costs.

The special hot melt adhesive particles for pearl cotton have achieved a comprehensive breakthrough: the rapid curing performance of immediate bonding upon melting can significantly shorten the production cycle. The stable weather resistance to high and low temperatures and moisture ensures the bonding strength in different environments. The zero wire drawing process has completely solved the problem of equipment cleaning, and the equipment failure rate has been significantly reduced.

Against the backdrop of the packaging industry's transformation towards green and intelligent development, the innovation of pearl cotton bonding technology is not only the result of market demand-driven but also a manifestation of the coordinated upgrading of the industrial chain. The launch of pearl cotton hot melt adhesive granules has provided a new solution to common industry problems, and its practical application effect is worthy of continuous attention and discussion by the industry.