Tetra Pak and Camme Pak have been newly upgraded: an efficient and stable straw bonding solution

Classification: Company News

Classification: Industry Information

2025-04-23

The current situation and demand pain points of the hot melt adhesive market

In the packaging industry, hot melt adhesives are widely used. From electronic packaging to food and beverage packaging, it has become an indispensable bonding material. However, in the process of bonding the straws of Tetra Pak and Camme Pak, traditional glue has exposed many problems. When in high-speed production, its curing speed is difficult to match, seriously slowing down the rhythm of the production line. Under low-temperature storage conditions, the performance drops significantly, causing the straws to fall off easily and failing to guarantee product quality.

New Type of straw Hot Melt Adhesive: Characteristics and Advantages

Wide applicability, suitable for various packaging

The straw hot melt adhesive we have developed has excellent universality. Whether it is the unique multi-layer composite structure of Tetra Pak or the special material of Camme Pak, it can perfectly fit and firmly bond the straw. This hot melt adhesive can be seamlessly integrated with different production equipment, regardless of brand or model, to meet diverse production needs and eliminate your concerns about equipment compatibility.

Low-temperature storage stability and long-term quality guarantee

Long-term low-temperature storage has always been a difficult problem in the packaging industry, but this hot melt adhesive can easily solve it. Even when stored for a long time in a low-temperature environment, its internal molecular structure remains stable, and it can still achieve the best bonding effect, ensuring that the straw of each Tetra Pak and Camme Pak is as stable as new, providing a long-term guarantee for product quality.

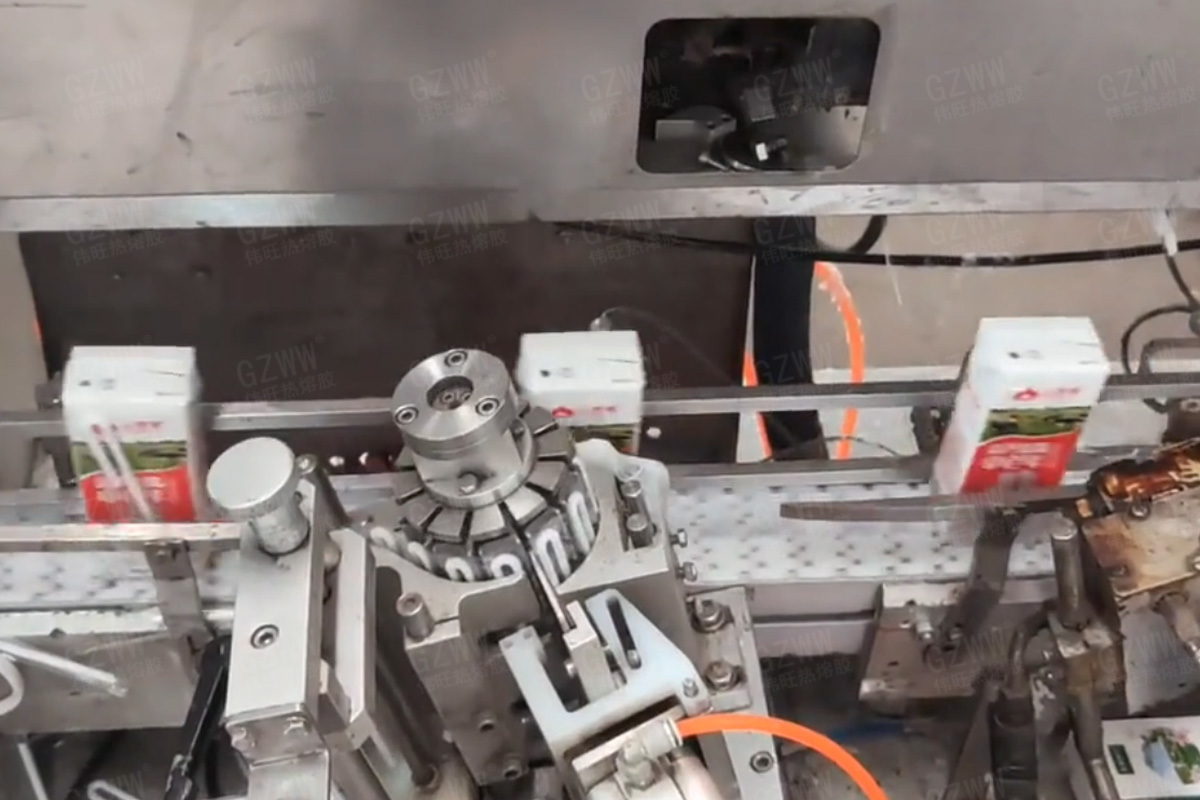

High-speed production adaptation has significantly enhanced efficiency

On a high-speed production line, time is money. This hot melt adhesive has an extremely fast curing speed and can easily keep up with the ultra-high-speed production pace of over 150 boxes per minute. When the production line is running at high speed, it cures rapidly, making the straws closely adhere to the packaging. This ensures that production efficiency is not affected by curing delays, significantly reducing downtime and waiting time, and greatly enhancing overall production capacity.

Environmentally friendly, safe and non-toxic, in line with industry standards

In the current era when food safety is of great concern, the environmental friendliness and safety of packaging materials are of vital importance. This straw hot melt adhesive fully complies with the relevant safety standards for food packaging. It has been strictly tested and is non-toxic and harmless, containing no substances harmful to the human body. During the production and use process, no harmful gases will be released or chemical pollution will occur, allowing purchasers and manufacturers to have no need to worry about environmental protection and safety issues at all.

Compared with traditional glue: all-round advantages are highlighted

Curing speed: Rapid curing, efficient production

Traditional glue has a slow curing speed. During high-speed production, it is necessary to wait for the glue to cure, which seriously restricts production efficiency. This hot melt adhesive, once applied, can cure in a short time, significantly shortening the production cycle.

Temperature resistance performance: Adaptable to temperature differences, stable and reliable

Traditional glue is sensitive to temperature. In a high-temperature environment, it is prone to softening, causing the straw to loosen. At low temperatures, it will become brittle again and the bonding strength will decrease. The new hot melt adhesive has excellent resistance to high and low temperatures. Whether it is the hot summer or the cold winter, and whether it is stored and transported in tropical or cold regions, it can stably maintain the bonding effect, ensuring that the product quality is not affected by temperature.

Bonding strength: Firm adhesion, reducing loss

The bonding strength of traditional glue is insufficient. During the subsequent transportation and storage of the product, the straw is prone to fall off, resulting in product loss. Our hot melt adhesive has an extremely high viscosity and combines closely with the materials of Tetra Pak and Camme Pak. Its bonding strength far exceeds that of traditional adhesives, significantly reducing the rate of straw detachment, minimizing production losses, and saving costs for enterprises.

Easy operation: Simplify the process and reduce costs

When traditional glue is used, it may require a complex mixing process and have high technical requirements for the operators. Hot melt adhesive is easy to operate. It only needs to be heated to the appropriate temperature and then applied for use. There is no need for complicated mixing, which reduces labor costs and time costs, and at the same time reduces production problems caused by operational errors.

The hot melt adhesive for straws specially designed for Tetra Pak and Konmei Pak breaks the limitations of packaging types and equipment with its all-scenario adaptability, overcomes the storage environment problem with its low-temperature long-lasting stability, matches the pace of modern production lines with its ultra-high-speed curing efficiency, and meets the strict standards of the food industry with its environmental protection and safety attributes. Compared with traditional glue, it is not only an upgrade in bonding efficiency, but also a full-chain value innovation from "production loss control" to "terminal quality guarantee".

RELATED INFORMATION

Pearl cotton dedicated hot melt adhesive pellets, with their all-scenario adaptability and environmentally friendly high performance, have become the innovative choice for pearl cotton manufacturers and packaging factories

View Details