New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

Classification: Company News

Classification: Industry Information

2025-06-09

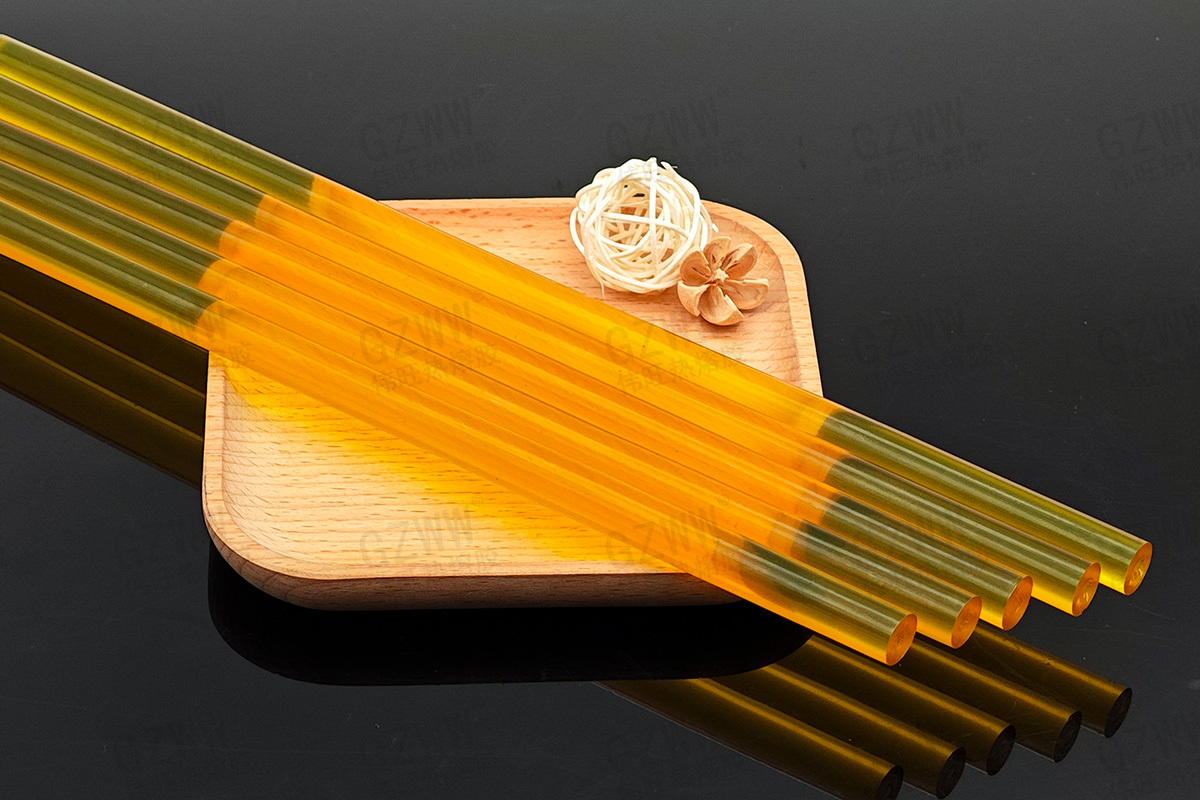

In the footwear manufacturing industry, the choice of adhesives directly affects product quality and production efficiency. As an innovative solution in the field of shoe material bonding, hot melt adhesive rods, with their core advantages of high efficiency, environmental friendliness and reliability, are revolutionizing traditional shoe-making processes and have become a key choice for many shoe enterprises to enhance their competitiveness.

I. Core advantages of hot melt adhesive sticks: Redefining the bonding standards for shoe materials

Hot melt adhesive rods are based on high molecular materials and achieve performance breakthroughs through scientific formulas, bringing multiple values to shoe production:

Rapid curing leads to a significant increase in production efficiency

After being heated and melted, the bonding and curing can be completed in a short time. Compared with the drying process of traditional water-based adhesives that takes several hours, it significantly shortens the production cycle. Especially in key processes such as the bonding of soles and uppers, the immediate bonding capability significantly enhances the efficiency of the production line, helping enterprises greatly increase their production capacity.

2. Strong adhesion, more reliable quality guarantee

It shows excellent bonding performance to various shoe materials such as leather, rubber, fabric and plastic. Even under harsh conditions such as frequent bending and high-intensity friction, it can ensure that the glue does not come apart for a long time, fundamentally reducing the rate of defective products and enhancing the durability of the products.

3. Green and environmentally friendly, in line with the new trends of the industry

It contains no toxic solvents such as formaldehyde and benzene, has no pungent smell, and meets the strict international environmental protection standards, helping enterprises easily cope with increasingly strict regulatory requirements. At the same time, it eliminates the complex solvent recovery and treatment process, reducing environmental protection investment and management costs from the source.

4. Flexible adaptation, simplifying the production process

There is no need for complicated surface pretreatment. By adjusting the temperature, it can meet the bonding requirements of different materials. Whether it is the gentle fixation of sensitive fabrics or the high-strength bonding of outdoor shoes in harsh environments, precise matching can be achieved through different types of hot melt adhesive rods, making the production process simpler and more efficient.

Ii. Limitations of Traditional Adhesives: Multiple Challenges of efficiency, safety and cost

Compared with hot melt glue sticks, traditional solvent-based or water-based adhesives have gradually revealed their shortcomings in the application of shoe materials:

Low efficiency slows down the production pace

Solvent-based adhesives need to be applied manually and then dried for a long time. The processing of single or double shoes takes several hours. Although water-based adhesives are relatively environmentally friendly, their drying speed is greatly affected by environmental humidity, which can easily lead to poor bonding, increase rework rates, and seriously affect production progress.

2. Prominent health and safety risks

The harmful chemicals contained in solvent-based adhesives pose a threat to workers' health when exposed to them for a long time, causing various occupational diseases. With the enhancement of environmental awareness, the use of such adhesives is restricted, and enterprises are facing increasing compliance pressure.

3. The complex process drives up the overall cost

The use of traditional glue requires additional equipment such as ventilation and fire prevention, which not only increases the initial equipment investment but also leads to high energy consumption and maintenance costs in the future. Especially for large-scale shoe manufacturers, the overall cost pressure is significant.

Iii. Scenario-based Application: The Diverse Values of Hot melt Adhesive Sticks in Shoe Material Production

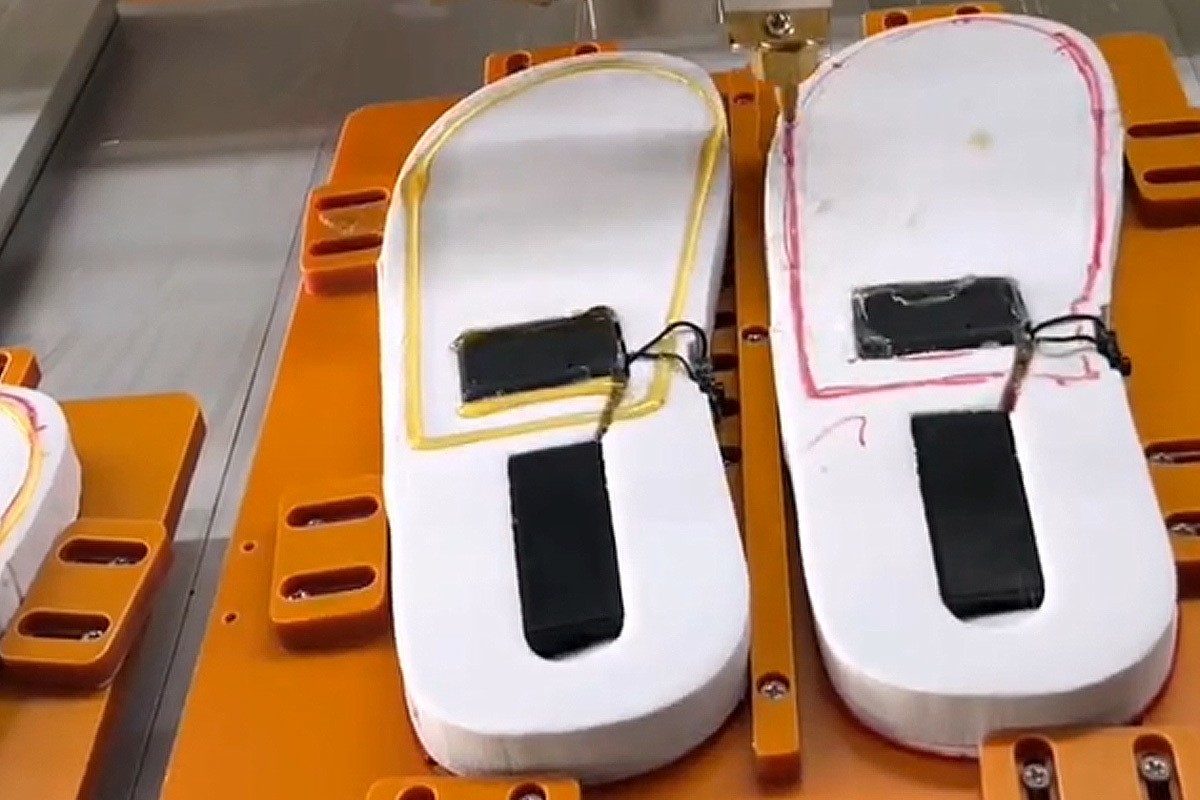

Disposable slippers: The ideal choice for efficient mass production

In response to the large-scale production demand for disposable slippers, hot melt adhesive sticks can quickly complete the bonding of non-woven fabric materials, significantly reducing the processing time of individual slippers. Moreover, they have excellent water resistance, completely solving the problem of traditional adhesives coming apart when exposed to water, and meeting the market's dual demands for the quality and efficiency of disposable products.

2. Upper folded edge: The guardian of exquisite craftsmanship and quality

In the edge folding process of the toe, toe and other parts of the shoe, the flexibility of the hot melt glue stick can perfectly fit the bending characteristics of materials such as leather and PU, ensuring uniform glue film and no glue overflow, making the edge folding effect more flat and firm, and enhancing the appearance refinement and grade of the product.

3. Sole composite: Reliable support for complex structures

For the composite bonding of complex structures such as the sole, midsole and support plate, the hot melt adhesive rod forms a tight connection through melting and penetration, which can adapt to the changes in high and low temperature environments and maintain stable performance for a long time, providing reliable guarantee for products with high requirements for sole strength, such as sports shoes and outdoor shoes.

4. Detail reinforcement: The key to enhancing the wearing experience

In terms of detailed treatments such as heel reinforcement and insole fixation, the high-strength bonding performance of hot melt adhesive rods can enhance the impact resistance of the heel, ensuring that the insole does not slip during exercise, and improving the comfort and practicality of the shoes from the details.

Iv. Selecting Hot Melt Adhesive Sticks: Seize the New Opportunities in the Footwear Industry

Dual drive of cost reduction and efficiency improvement

Reduce labor time consumption, lower material waste, optimize the cost structure from the production source, and create a greater profit margin for the enterprise.

2. Quality upgrade wins reputation

Significantly improve the bonding quality of products, reduce after-sales problems, and help enterprises build a high-quality brand image.

3. Green manufacturing builds barriers

In line with the global environmental protection trend, it gains the favor of international brand procurement by virtue of its environmental protection advantages and opens the door to the high-end market.

Hot melt adhesive sticks, as an important driving force for the upgrading of the shoe-making industry, are promoting the industry's transformation towards "green intelligent manufacturing" through their efficient, environmentally friendly and reliable features. As a supplier specializing in shoe material bonding solutions, we always provide customized hot melt adhesive products for shoe enterprises of different scales with innovative formulas and professional services, helping customers gain an edge in competition and jointly open a new chapter of high efficiency and environmental protection in the shoe manufacturing industry.

RELATED INFORMATION

Analysis of the core value of hot melt adhesive sticks in the shoe-making field: With advantages such as rapid curing, high-strength bonding, environmental friendliness, and flexible adaptability, compared with the shortcomings of traditional adhesives such as low efficiency, toxicity, and complex processes, it precisely solves the bonding problems in scenarios such as disposable slippers, upper edge folding, and sole lamination, helping shoe enterprises reduce costs, improve efficiency, upgrade quality, and seize the opportunity of green manufacturing.

View Details